Cable lugs are essential components in electrical and mechanical connections. They provide a secure and reliable way to attach cables to terminals, bus bars and other equipment. They ensure strong conductivity and prevent issues like overheating or loose connections, which can lead to system failures. Whether in industrial machinery, automotive wiring or home electrical systems, using the right cable lug is crucial for efficiency and safety.

With various types available, selecting the correct one can be challenging. Factors such as material, design and application all play a role in determining the best option. Some lugs are designed for high-current industrial use, while others cater to compact spaces or corrosion-resistant environments. Understanding the differences helps in making the right choice, ensuring durability and optimal performance.

This guide explores the most common types of cable lugs, their applications, and key benefits. By the end, you'll have a clear understanding of which cable lug best suits your needs.

90 Degree Angled Cable Lugs

90-degree angled cable lugs are designed for tight spaces where a standard straight lug would be difficult to install. Their bent design allows for efficient cable routing in compact areas while maintaining a secure connection.

Common Applications

- Automotive and marine wiring, where space is limited.

- Switchboards and control panels, ensuring organised cabling.

- Battery and power distribution systems, fitting within confined enclosures.

Material and Durability

Typically made from copper or tinned copper, these lugs offer excellent conductivity and corrosion resistance, making them ideal for long-term use in demanding environments.

Compression Cable Lugs

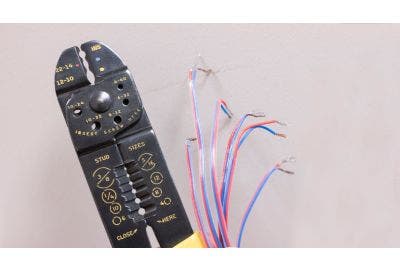

Compression cable lugs create strong, long-lasting connections by crimping the lug onto the cable using crimping tools. This method ensures a secure bond, reducing resistance and improving conductivity.

Benefits of Compression Lugs

- Reliable Connection – Prevents loose connections and overheating.

- Durability – Withstands vibration, making them ideal for industrial use.

- Consistent Performance – Ensures a uniform electrical connection.

Common Applications

- Electrical panels and switchgear

- Renewable energy systems

- Industrial machinery

- Automotive and marine wiring

These lugs offer a cost-effective, secure solution for high-performance electrical connections.

Forked Cable Lugs

Forked cable lugs, also known as spade terminals, have an open-ended design that allows easy connection and disconnection without removing the terminal screw completely.

When to Use Forked Lugs

- Control panels and circuit breakers, where quick wiring changes are needed.

- Automotive and marine applications, allowing for easy removal and reattachment.

- Household and industrial electrical systems, providing a secure yet accessible connection.

Forked Lugs vs. Ring Terminals

Unlike ring terminals, which require the screw to be fully removed for installation, forked lugs can simply slide into place, speeding up assembly time. However, they may not provide the same level of vibration resistance, making ring terminals a better choice for high-vibration environments.

Tubular Cable Lugs

Tubular cable lugs are heavy-duty connectors designed for high-current and industrial applications where durability and conductivity are essential. Made from copper or aluminium, they provide a secure connection by crimping (or soldering, although this is often not the preferred method) the cable into the lug barrel, ensuring minimal resistance and maximum efficiency.

Key Features

- Thick-walled design – Enhances electrical performance and heat dissipation.

- Crimped or soldered installation – Provides a strong and long-lasting connection.

- Wide range of sizes – Suitable for different cable thicknesses and voltage requirements.

Common Applications

- Power distribution boards and switchgear

- Industrial machinery and control panels

- Renewable energy systems (solar, wind, and battery storage)

Their robust construction makes tubular lugs a reliable choice for demanding environments.

Aluminium Cable Lugs

Aluminium cable lugs are a lightweight and cost-effective option for electrical connections, particularly in power distribution, industrial settings and renewable energy systems. They provide good conductivity while being more affordable than copper alternatives, making them ideal for large-scale installations.

Why Use Aluminium Lugs?

Cost-Effective – More affordable than copper, reducing overall project costs.

Lightweight – Easier to handle and install, especially in large wiring systems.

Corrosion Resistance – Can be tin-plated to prevent oxidation and extend their lifespan.

Common Applications

- Overhead power lines and electrical grids

- Industrial wiring systems and switchgear

- Solar farms and wind energy projects

Proper installation is key to preventing oxidation, often requiring compatible compounds to ensure a strong electrical connection.

Bi-Metallic Cable Lugs

Bi-metallic cable lugs connect aluminium conductors to copper terminals, preventing galvanic corrosion. These lugs feature an aluminium barrel and a copper palm, joined through friction welding for a strong connection.

Why Use Bi-Metallic Lugs?

- Prevents Corrosion – Stops oxidation between aluminium and copper.

- Enhances Electrical Efficiency – Reduces resistance and overheating.

- Versatile Applications – Used in power distribution and renewable energy systems.

Common Applications

- Electrical transmission networks

- Solar and wind energy systems

- Industrial switchboards

These lugs improve connection reliability and performance in demanding environments.

Copper Cable Lugs

Copper cable lugs are widely used due to their high conductivity, durability and corrosion resistance. Copper ensures minimal energy loss and efficient power transfer, making these lugs ideal for applications requiring a strong, reliable connection.

Why Choose Copper Lugs?

- Superior Conductivity – Maximises efficiency with low resistance.

- Corrosion Resistance – Many are tin-plated for added protection.

- Long-Term Durability – Withstands harsh environments and heavy loads.

Common Applications

- Power distribution and switchgear

- Automotive, marine and industrial wiring

- Renewable energy systems

Available in various types and sizes, copper lugs provide a long-lasting solution for electrical connections.

Nickel Cable Lugs

Nickel cable lugs are designed for high-temperature and corrosive environments, where standard lugs may degrade. Nickel’s exceptional resistance to heat, oxidation, and chemicals makes these lugs ideal for demanding applications.

Why Use Nickel Lugs?

- High-Temperature Resistance – Performs reliably in environments exceeding 600°C.

- Corrosion Protection – Resists oxidation, acids and harsh chemicals.

- Durability – Withstands mechanical stress and extreme conditions.

Common Applications

- Aerospace and defence industries

- Industrial furnaces and power plants

- Marine and offshore installations

Though more expensive than copper or aluminium, nickel lugs offer unmatched reliability in extreme conditions.

Stainless Steel Cable Lugs

Stainless steel cable lugs offer high strength and corrosion resistance, making them ideal for marine, industrial, and outdoor environments.

Why Use Stainless Steel Lugs?

- Excellent Corrosion Resistance – Ideal for marine and offshore applications.

- High Mechanical Strength – Withstands heavy loads.

- Long-Lasting Performance – Resists rust and oxidation.

Choosing the right cable lug is essential for ensuring a secure, efficient, and long-lasting electrical connection. The correct selection depends on factors such as material, application, and environmental conditions. Using the wrong lug can lead to poor conductivity, overheating, and potential system failures.

From compression and tubular lugs for high-current applications to bi-metallic and stainless steel options for corrosion resistance, each type serves a specific purpose. Selecting the best one improves safety, durability, and performance.

To explore a wide range of high-quality cable lugs, contact us for an expert for tailored recommendations.