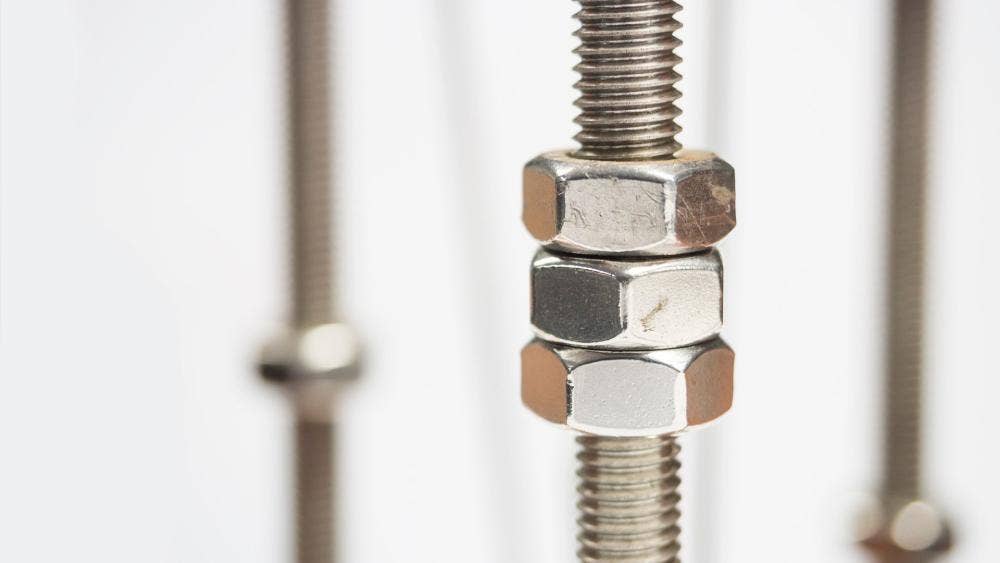

Choosing the correct metric bolt size is essential in construction, engineering and DIY projects. Metric bolts, measured in millimetres, are widely used across industries for their precision and standardisation. However, understanding measurements like diameter, pitch and length, as well as interpreting bolt strength grades, can be challenging for those unfamiliar with the terminology.

This guide simplifies these concepts, looking at how metric bolts are measured, the differences from Imperial bolts and their various applications. It also provides practical advice for selecting the right bolt type and size for your needs, helping you complete projects efficiently and with confidence.

Understanding Metric Bolt Sizes

To work effectively with metric bolts, understanding their measurement system and the terminology associated with their sizing is essential. Metric bolts follow a standardised system that uses millimetres, making it easier to achieve precision and consistency across various applications.

How Metric Bolts Are Measured

The dimensions of a metric bolt are defined by three key measurements:

- Diameter

- Tread pitch

- Length

The diameter refers to the width of the threaded portion, often called the nominal diameter. This measurement is required to provide compatibility with nuts or pre-threaded holes; for example, an M8 bolt has a diameter of 8mm, making it suitable for specific applications.

Thread pitch measures the distance between adjacent threads, with a smaller pitch indicating fine threads and a larger pitch signifying coarse threads.

Fine threads are ideal for high-precision tasks, while coarse threads perform better with materials like wood or plastic.

Finally, the length of a bolt is measured from the base of the head to the tip of the threaded portion. For countersunk bolts, the full length is measured, whereas for others, only the shaft length is considered.

This measurement helps determine whether a bolt will effectively secure materials without being too short or excessively long.

Accurate measurement of these dimensions is needed to select a bolt that fits correctly and provides a strong, reliable hold. Using incorrect dimensions can lead to poor performance, material damage, or even project failure.

Key Terms: Diameter, Pitch and Length

Understanding the terms used to describe metric bolts is essential for selecting the right one. The diameter refers to the width of the threaded part of the bolt, which determines its fit with a matching nut or hole. Thread pitch describes the space between threads, indicating how tightly they are spaced. Length is the total distance from the bolt's head to its tip, showing how far it will penetrate the material.

These terms form the foundation of metric bolt identification, allowing users to confidently select the right type for their projects.

Commonly Used Metric Bolt Sizes

Metric bolts come in a wide range of sizes; for a quick overview, here’s a table summarising commonly used metric bolt sizes, their key specifications, and typical applications:

| Bolt Size | Main Diameter (mm) | Inner Diameter (mm) | Thread Pitch (mm) | Typical Applications |

|

M1 |

1 | 0.729 | 0.25 |

Precision instruments, watches, electronics

|

|

M1.1 |

1.1 | 0.829 | 0.25 | |

|

M1.2 |

1.2 | 0.929 | 0.25 | |

|

M1.4 |

1.4 | 1.075 | 0.3 | |

|

M1.6 |

1.6 | 1.221 | 0.35 |

Small electronics, precision instruments |

|

M1.8 |

1.8 | 1.421 | 0.35 | |

|

M2 |

2 | 1.567 | 0.4 | |

|

M2.2 |

2.2 | 1.713 | 0.45 | |

|

M2.5 |

2.5 | 2.013 | 0.45 | |

|

M3 |

3 | 2.459 | 0.5 |

Electronics, small machinery, automotive, furniture assembly |

|

M3.5 |

3.5 | 2.85 | 0.6 | |

|

M4 |

4 | 3.242 | 0.7 | |

|

M4.5 |

4.5 | 3.688 | 0.75 | |

|

M5 |

5 | 4.134 | 0.8 | |

|

M6 |

6 | 4.917 | 1 | |

|

M7 |

7 | 5.917 | 1 | |

|

M8 |

8 | 6.647 | 1.25 |

Automotive, construction, medium-to-heavy duty tasks |

|

M9 |

9 | 7.647 | 1.25 | |

|

M10 |

10 | 8.376 | 1.5 | |

|

M11 |

11 | 9.376 | 1.5 | |

|

M12 |

12 | 10.106 |

1.75 |

|

|

M14 |

14 | 11.835 | 2 |

Heavy machinery, construction equipment |

|

M16 |

16 | 13.835 | 2 | |

|

M18 |

18 | 15.394 | 2.5 | |

|

M20 |

20 | 17.294 | 2.5 | |

|

M22 |

22 | 19.294 | 2.5 | |

|

M24 |

24 | 20.752 | 3 | |

|

M27 |

27 | 23.752 | 3 | |

|

M30 |

30 | 26.211 | 3.5 | |

|

M33 |

33 | 29.211 | 3.5 | |

|

M36 |

36 | 31.67 | 4 | |

|

M39 |

39 | 34.67 | 4 | |

|

M42 |

42 | 37.129 | 4.5 | |

|

M45 |

45 | 40.129 | 4.5 | |

|

M48 |

48 | 42.857 | 5 | |

|

M52 |

52 | 46.587 | 5 | |

|

M56 |

56 | 50.046 | 5.5 | |

|

M60 |

60 | 54.046 | 5.5 | |

|

M64 |

64 | 57.505 | 6 | |

|

M68 |

68 | 61.505 | 6 |

These sizes are readily available in most hardware stores and are versatile enough to cover a wide range of tasks. When selecting a size, consider factors like material type, the load-bearing requirements and the type of project.

Keeping a selection of commonly used sizes on hand can save time and frustration, especially for those who frequently undertake varied projects.

Breaking Down the Metric Bolt Numbering System

Understanding the metric bolt numbering system is essential for selecting the correct bolt for your project. This guide explains how to interpret bolt dimensions, decode strength grades and compare metric and Imperial systems to simplify decision-making.

What Do the Numbers on Metric Bolts Mean?

Metric bolts use a code like M8x1.25x30 to convey key details:

- M: Indicates the metric measurement system, with sizes in millimetres.

- 8: Specifies the bolt's nominal diameter, here 8mm.

- 1.25: Defines the thread pitch, or the gap between threads, in millimetres. Smaller numbers indicate finer threads.

- 30: Refers to the bolt’s length, measured from the base of the head to the tip, in millimetres.

For example, an M8x1.25x30 bolt has an 8mm diameter, a 1.25mm thread pitch and a 30mm length. Ensuring the right size and pitch prevents mismatched components and secures proper assembly.

How to Interpret Metric Bolt Strength Grades

Strength grades, marked on the bolt head as pairs like 8.8 or 10.9, describe the bolt’s capacity to handle loads:

- First Number: Denotes tensile strength in hundreds of megapascals (MPa). For example, an 8.8 bolt can handle 800 MPa.

- Second Number: Represents the yield strength multiplier. In 8.8, the yield strength is 80% of the tensile strength (640 MPa).

Common Grades:

- 8.8: Suitable for general use, balancing strength and affordability.

- 10.9: Designed for higher-stress environments like machinery.

- 12.9: Ideal for demanding, high-load applications.

Choosing the right grade is critical. A lower grade, like 8.8, suits lighter tasks, while grades 10.9 or 12.9 meet heavy-duty demands.

Metric vs. Imperial Numbering Systems

Metric and Imperial bolts differ in both measurement units and terminology:

- Metric: Uses millimetres for dimensions and thread pitch.

- Imperial: Specifies dimensions in inches and thread counts as threads per inch (TPI).

Examples:

- Metric: M10x1.5x50 – 10mm diameter, 1.5mm pitch, 50mm length.

- Imperial: 3/8-16x2 – 3/8-inch diameter, 16 TPI, 2-inch length.

Mixing systems can lead to errors. To minimise issues:

- Use conversion charts for accurate comparisons.

- Separate tools designed for metric and Imperial fasteners.

- Opt for metric bolts where possible, as they are more standardised globally.

Types of Metric Bolts and Their Applications

Choosing the right metric bolt depends on the materials, environment and specific requirements of your project. Below are common bolt types, their features and ideal uses:

- Hex Bolts: With their six-sided heads, hex bolts are versatile and easy to tighten with a wrench or socket. They are commonly used in construction, machinery assembly and automotive work for their strength and accessibility.

- Machine Bolts: Designed for precision fastening, machine bolts are typically paired with nuts to create secure joints in metalworking and industrial machinery.

- Carriage Bolts: Known for their rounded heads and square necks, these bolts are ideal for wooden structures like furniture or fencing. The square neck ensures a stable fit by preventing the bolt from rotating during tightening.

- Socket Head Bolts: These bolts feature a cylindrical head and require an Allen key for fastening, making them perfect for compact spaces or applications requiring a flush finish, such as electronics or machinery with tight tolerances.

- Flanged Bolts: With a washer-like flange under the head, flanged bolts distribute pressure evenly, protecting softer materials and providing stability in high-stress applications.

Material and Environmental Considerations

For outdoor or corrosive environments, stainless steel bolts are preferred for their resistance to rust. High-tensile bolts, such as grade 8.8 or above, are recommended for projects involving heavy loads or critical safety requirements.

Best Materials for Metric Bolts

Metric bolts are manufactured from various materials, each with its advantages depending on the application.

Steel is the most commonly used material for metric bolts, offering durability and strength. It is a cost-effective option for general-purpose use, making it a reliable choice for a wide range of projects.

Stainless steel bolts, on the other hand, are favoured for their corrosion resistance. They are an excellent choice for outdoor projects or any environment exposed to moisture, such as marine settings.

Brass bolts, although softer than steel, are valued for their corrosion resistance and are often used in decorative or electrical applications where aesthetics or conductivity is needed.

For applications requiring improved strength and durability, alloy steel bolts are a strong contender. They are often employed in industrial machinery or other high-stress situations where performance under load is a priority.

Choosing the right material for your bolts means they perform well in their intended environment, whether that’s resisting rust outdoors or handling heavy loads in industrial settings.

Metric Bolt Thread Types

The thread type of a metric bolt is a significant factor that affects how it performs in various applications. Threads determine how securely a bolt grips, its load-bearing capacity and its compatibility with corresponding nuts or pre-threaded holes. Understanding thread types is essential for achieving strong and reliable connections.

Coarse vs. Fine Threads

Metric bolts have coarse or fine threads, each suited to specific tasks.

Coarse threads, with larger thread pitch, are easier to assemble, resistant to stripping and ideal for softer materials like wood or plastic. They are also less affected by dirt and debris.

Fine threads, with a smaller pitch, provide stronger holding power and excel in precision or high-vibration environments, such as metalworking. However, fine threads are more delicate and require careful handling.

Selecting the right thread type depends on the application—for example, coarse threads suit wooden frames, while fine threads are better for securing engine components.

How to Measure Thread Pitch

Thread pitch is a key measurement that defines the distance between adjacent threads on a bolt. Measuring it accurately is essential to selecting the right bolt for your needs. To measure thread pitch, you can use a thread pitch gauge, a tool specifically designed for this purpose. Here’s a step-by-step guide:

- Place the thread pitch gauge over the threads of the bolt.

- Align the teeth of the gauge with the threads.

- Identify the number marked on the gauge that fits perfectly with the bolt’s threads. This number represents the pitch, measured in millimetres.

For example, if the gauge indicates a pitch of 1.25, this means the distance between threads is 1.25mm. Accurately measuring the thread pitch compatibility with corresponding nuts avoids mismatched fittings, which can weaken the connection or cause damage.

Why Thread Type Matters for Fastening

The type of thread on a bolt influences its overall performance, including how it distributes force and holds materials together.

Coarse threads are better suited for applications where resistance to stripping and faster assembly are required. This applies in areas such as construction or woodworking.

Fine threads, on the other hand, are ideal for precision tasks where a tighter grip and better resistance to loosening under vibration are required, such as in automotive or aerospace applications.

Using the wrong thread type can lead to problems such as loose connections, material damage, or even project failure. For instance, attempting to use a coarse-threaded bolt in a fine-threaded nut will result in poor alignment and insufficient grip. By understanding the differences between coarse and fine threads, you can select the right bolt for your project and avoid common mistakes.

How to Choose the Right Metric Bolt for Your Project

Selecting the correct metric bolt for your project involves more than simply picking a size off the shelf. Factors such as size, load requirements, materials and tools all play a significant role in making sure your bolt functions as intended. This section offers practical guidance to help you make an informed decision.

Matching the Bolt Size to the Application

Choosing the appropriate bolt size is essential for structural integrity and reliable performance. Start by considering the materials involved and the type of project. For instance, smaller bolts like M6 are often sufficient for furniture assembly, while larger bolts such as M10 are better suited for heavy-duty tasks like securing machinery or structural beams.

To estimate the required bolt size, take into account the thickness of the material you are fastening. The bolt should be long enough to pass through the material and allow for secure fastening with a nut or pre-threaded hole, without being so long that it protrudes unnecessarily. Precision is key, as a poorly sized bolt can compromise the stability of your assembly and lead to safety risks.

Considering Load and Strength Requirements

The load-bearing capacity of a bolt is determined by its diameter, thread type and strength grade. Before selecting a bolt, evaluate the forces it will need to withstand. For example, a bolt used in a light-duty application, such as securing a small bracket, may only need a basic strength grade like 4.6. However, bolts for structural or high-stress environments, such as automotive or industrial machinery, often require higher grades like 10.9 or 12.9 to handle greater loads.

When working on structural projects, it is wise to factor in a safety margin. This means choosing a bolt with a higher load-bearing capacity than the calculated requirements to account for unexpected stresses. This approach improves the durability and reliability of the assembly.

Tools and Techniques for Measuring Bolts

Accurate measurement is fundamental when choosing metric bolts. Using the right tools helps in selecting bolts that fit properly and perform as intended. Here are the essential tools and their uses:

- Callipers: These are used to measure the diameter of the bolt, including the threaded portion.

- Thread Pitch Gauge: This tool helps you determine the thread pitch by matching the bolt’s threads to the corresponding gauge teeth.

- Measuring Tape or Ruler: These are useful for measuring the length of the bolt from the base of the head to the tip.

To measure a bolt effectively, begin by determining the diameter using callipers. Next, use a thread pitch gauge to find the pitch value. Finally, measure the length to make sure it is appropriate for your project. Recording these measurements can save time when selecting bolts in the future or when replacing parts.

When choosing a bolt, consider the environment where it will be used. For outdoor or damp environments, stainless steel bolts offer excellent corrosion resistance, whereas standard steel bolts are typically sufficient for indoor applications. Additionally, the compatibility between bolts, nuts and washers by selecting components with matching thread types and grades.

Taking the time to evaluate these factors helps reduce the risk of errors, improve the longevity of your project and avoid costly mistakes. Whether you are assembling furniture, constructing a building, or repairing machinery, following these guidelines will help you choose the right bolt for the job.

Understanding metric bolt sizes means better performance and safety in your projects. In this guide, we have covered everything from measurements and strength grades to applications and materials, hopefully equipping you with the knowledge to make informed decisions for your project.