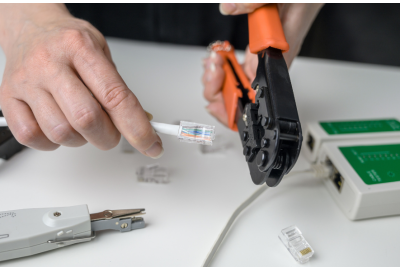

Each crimp needs a specific tool for the terminations to be reliable. Without using the right crimping tool and crimping dies, the crimp can be unsecure or cut into the connector, depending on whether it is too loose or too tight. Different terminals require different tools, so it is crucial that you find the one you need for your terminal and wire combination. But what crimping tool do you require?

If you are wondering how to establish what tools you need, we have compiled what you need to think about and what the different tools are, so you can find the right one for your task. Take a look at the different types of crimping tools available and the factors you need to consider before purchasing one.

What is a Crimp Tool?

Specifically, this type of tool is designed to connect metal and electrical components together by deforming the barrel around the wire, fusing them together in the process. Some of these crimp tools have fixed dies, whereas for others the dies are interchangeable, and these are what causes the crimp to form. A range of crimping tools are available, such as hand-held crimp tools, and each is used to form a different crimp.

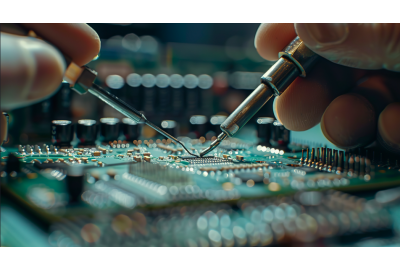

Is Crimping Better than Soldering?

Both crimping and soldering can achieve similar results, but the one you use depends on the materials you have available and your specific requirements. Soldering is a more time-consuming process and requires more skill, as well as heat. As soldering is lead-free, higher temperatures are needed for the solder to be completed properly. In contrast, crimping tends to be favoured as, more often than not, it is cheaper and more convenient. Some metals also do not take to solder, which means crimping is a more suited process to connect the two metals together.

Duties of Crimping Tools

Light-duty Crimping Tools

How much the handle is squeezed affects how much pressure is applied, which is why the pressure varies every time light-duty crimping tools are used. These simple tools can become uncomfortable if they are used for a lot of connections, and the handle protection they offer is limited. Instead, they are more suited for crimping a limited number of connections.

Standard Duty Crimping Tools

In comparison to light-duty crimping tools, these tools last longer and are of better quality. Standard duty crimping tools are the most common type used by people at home, and they are more comfortable to use because of their handle protection. When using these tools, an adjustable ratchet mechanism controls the pressure, enabling said pressure to be consistent and repeated.

Heavy-duty Crimping Tools

These are the tools used by professionals and they have the longest lifespan out of the three types. Heavy-duty crimping tools are designed for professionals, mechanics or converters in particular, and they are more comfortable to use. They are ideal for when repeatable crimps need to be made.

Types of Crimping Tools

1) Manual Handheld Crimping Tools

These are portable and inexpensive tools that are effective to use. Manual hand oerated crimping tools use swappable die sets and, using a manual ratchet crimping tool, you can do up to 180 terminations within an hour.

Featured Product - Klauke K 06 D 10mm² - 120mm² Crimping Tool with Ratchet

This tool from Klauke has a crimp range of between 10mm² and 120mm² and uses revolving dies for a wide crimping range.

2) Electric Handheld Crimping Tools

If you want consistent crimps, cordless crimp tools can achieve this. They are powered by batteries and have modular crimp heads. Electric handheld crimp tools can do a maximum of 200 terminations within an hour.

Featured Product - Klauke EK WF 120 ML 6mm² - 120mm² Battery Powered Crimp Tool (10kN/40kN)

Making little noise, this electric crimping tool has an innovative square (comb) pressing, which doesn't require a change of crimping dies.

3) Manual Benchtop Crimping Tools

When compared to manual handheld crimp tools, these do not need as much force to be applied. They are person-operated instead of being powered by electricity or batteries and they can do approximately 180 terminations in an hour.

4) Electric Benchtop Crimping Tools

With the ability to have high rates for producing crimps, electric benchtop crimp tools can do 2000 connections in an hour and are tabletop designs. They also form high-quality crimps and use a fixed-speed motor.

Featured Product - Klauke THK 120 10mm² - 400mm² Hydraulic Crimping Tool for Workbench Mounting - 120kN

This Klauke model has a large crimping range and is BG-compliant. The Klauke Series 13 interchangeable dies should be used with this tool.

5) Mountable Pneumatic Crimping Tools

This type of tool can be clamped into place on a workbench or can be handheld, and it can do approximately 600 connections in an hour. Mountable pneumatic crimp tools are air-powered, and they are attached to an air supply. Sometimes they are connected to an operational switch. These tools offer a crimping solution that is both flexible and effortless.

6) Hydraulic Handheld Crimping Tools

Despite being hand-operated, these hydraulic crimping tools require less effort than other manual crimping tools. They also use hydraulic fluid, which is used to compress the die by having the fluid pumped into the tool.

Featured Product - Klauke EK 135 FTCFB 10mm2 - 630mm2 Bosch Battery-Powered Hydraulic Crimping Tool - 135kN

With this hydraulic handheld tool, a crimping cycle is approximately 10-11 seconds and it has a pistol-style grip. The crimping force is 13.5 t, and it has a rotatable closed head.

Factors to Consider:

1) Volume

If you are looking at what type of crimping tool you need, you have to consider the volume of operation you require. For example, if your volume of operation is high, you will require an automatic tool, such as a pneumatic tool or a hydraulic tool. Hand crimping is still used in factories by most production lines.

A medium volume of operation can find a ratchet crimping tool ideal, as it can offer improved quality control. This means the full range of motion required is used by the operator so the crimp can be completed successfully. This type of production line will need to use tools that are both rugged and ergonomic.

For lines that have a smaller volume of operation, crimping tool sets with interchangeable dies and multi-purpose tools are preferred. This is because you won’t need individual tools, making it a more economical option for smaller businesses and shops.

2) Wire Gauge and Crimp Profile

This is how crimp tools are sized and when buying crimp tools, it is something you need to think about. The wire gauge that the tool can be used on is what determines the size of said crimp tool, and an incorrect size is what can cause the crimp to be too loose or too tight. The measurement used is the American Wire Gauge (AWG).

3) Crimp Profile

When performing a crimp, the profile of the terminal is specific, and each one needs a particular die for the crimp to work effectively. Most experts can determine which die needs to be used through the shape of the jaw. However, you need to be certain which die you need for the crimp you are going to do, and that you are buying the right one.

4) Open/Closed Barrel

There are two different types of terminal, and these are closed barrel and open barrel.

Open barrel terminals are very effective and are the most commonly used terminal for applications with high volume and automotive wire harnesses. The ‘F’ crimp is the style that is usually used for open barrels, and this type of terminal offers the best resistance against corrosion and vibration.

When looking at the wire terminal market, closed barrel terminals are the ones you will most often see. They can either be insulated or non-insulated and are available in a range of sizes and shapes. They come in quick connections and most often use either a hexagon or oval-style crimp.

5) Insulated or Non-Insulated

If you use the incorrect crimping tool, it can cause damage. If you have insulated terminals, the ideal tool has rounder jaws than its non-insulated counterpart. This is because the rounder jaws are less likely to damage the insulation of the terminal. If you use a non-insulated tool on an insulated terminal, it can lead to an over or under-crimp being formed and can cause damage to the insulation sleeve.

6) Terminal Material

The terminal manufacturer should mention the thickness of the material and what type of material was used in the terminal. Different materials have different properties, so they are used in varying circumstances. Most crimp standards can be found on the pre-insulated copper ring terminals, but this does not include open-barrel ones.

Some of the materials used for terminals include:

- Aluminium, which is used because it is a lightweight material

- Brass, which is used because it is a hard material

- Bronze, which is used because it can withstand high pressure

- Copper, which is used because of its conductivity

- Nickel, which is used because it melts at a high temperature

7) Specifications from Manufacturer

The crimp tool that needs to be used is specified by most manufacturers. Refer to the manufacturer's specifications, which will tell you which tools to use. In this particular circumstance, a multipurpose crimper tends not to be effective.

The tools should comply with UL guidelines. As an accredited standards developer, UL provide standards against which tools can be measured to ensure they are safe for use.

8) Warranty Requirements

When using terminals, some brands will have specifications concerning which crimping tools can be used. For some, the warranty may state that the only tools that can be used with a specific brand of terminal are their brand of crimping tools. Not using these tools can then make the warranty void. To maintain certifications with the brand, using the branded crimping tools stated is advised.

Finding the right crimping tools are important to ensure you can crimp your terminals correctly, but the tool isn’t the only part that you need to consider. Heamar have a range of crimping tool accessories that can complement your chosen tool and help you perform the crimps you need to. Take a look and see how we can help you find the right tools and accessories today.