Crimping tools are vital in many industries, ensuring strong and reliable connections. They work by deforming wires, cables, or other materials to hold them together, promoting safety and efficiency in fields like electrical work, telecommunications, aerospace and automotive industries.

Originally, simple hand tools were used, but crimping tools have advanced significantly. The 20th century brought pneumatic, electrical and hydraulic versions, improving efficiency and precision. Today, these tools are essential in many sectors due to their reliability and advancements.

Modern crimping tools come in various designs, each suited for different tasks. This guide will explore the types of crimping tools, their uses, factors to consider when buying them, and tips for maintenance. By the end, you'll know how to select the right tool and keep it in great condition.

Types of Crimping Tools

Understanding the differences between these tools can help you select the right one for your tasks. Here, we will look at four main types: handheld, hydraulic, electrical, and mechanical.

Handheld Crimping Tools

These are widely used due to their portability and ease of use. These tools are lightweight and can be easily carried to different locations, making them ideal for both professionals and DIY enthusiasts.

One of the main advantages of hand-held crimping tools is their cost-effectiveness. They are generally more affordable than hydraulic or electrical tools, making them accessible to a broader audience. However, the manual effort required to operate these tools can be a drawback, particularly during prolonged use or when working with thicker materials. This can lead to hand fatigue, limiting the duration for which these tools can be used comfortably.

When choosing the right tool, it is advised to consider features such as ergonomic handles, which can significantly reduce hand strain during extended use. Additionally, tools with adjustable dies offer versatility, allowing users to crimp various connectors with a single tool. Durability is also a key factor, so opting for tools made from high-quality materials like steel ensures longevity and reliability.

Hydraulic Crimping Tools

These tools are designed for heavy-duty tasks that require significant force, making them ideal for industrial and large-scale projects, such as those found in the construction, renewable energy, automotive repair and heavy machinery maintenance industries.

Hydraulic crimping tools are particularly effective for crimping large cables and connectors, where a strong and secure bond is essential.

The primary advantage of these tools is their ability to handle tough materials and larger connections with ease, providing consistent and reliable crimps every time. However, their bulkier size and the need for more maintenance, especially concerning the hydraulic system, can be seen as disadvantages. Despite this, their power and efficiency make them indispensable for demanding applications.

When selecting a hydraulic crimping tool you need to look for features such as interchangeable dies, which allow the tool to accommodate different sizes and types of connectors. Some models also include a pressure gauge to monitor the force applied, ensuring accurate and safe crimping. A sturdy construction, often with reinforced components, is required to withstand the high pressures involved in hydraulic crimping.

Battery Powered Crimping Tools

Battery powered crimping tools offer the convenience of automated crimping, which significantly speeds up tasks. These tools are powered by electricity or batteries, reducing the need for manual effort and making them ideal for repetitive tasks, particularly in high-volume settings such as the electrical and telecommunications industries. They are efficient at crimping a variety of connectors and cables, providing uniform crimps with minimal user intervention.

The main advantage of these tools is the speed and ease of use they offer, which is particularly beneficial in professional environments where time is a critical factor. However, they are generally more expensive than manual crimping tools, and their reliance on battery power can be a limitation in remote locations or during extended tasks. To maintain efficiency, purchasing additional batteries can help ensure continuous operation without frequent recharging interruptions.

Additionally, some models feature quick-change dies, which facilitate rapid switching between different crimping tasks improving overall efficiency.

Mechanical Crimping Tools

Ratcheting crimp tools, a type of mechanical crimping tool, strike a balance between handheld and hydraulic crimpers in terms of power and convenience. These tools operate through manual leverage and often include a ratcheting mechanism for consistent crimps.

This design makes them suitable for a wide range of applications, including electrical work, cable assembly, and network installations. The main benefit of ratcheting crimp tools is their ability to deliver more power than handheld tools while remaining more portable and less bulky than hydraulic options.

The ratcheting mechanism is particularly valuable, ensuring each crimp is applied with uniform pressure for reliable connections. However, some manual effort is still required, which can be tiring over extended periods, and they may be slower than electrical tools. When selecting a ratcheting crimp tool, consider models with ergonomic designs to reduce fatigue.

This ratcheting mechanism provides precise control over the crimping process, ensuring consistent results, while adjustability for different connector sizes enhances their versatility, making these tools valuable for various professional applications.

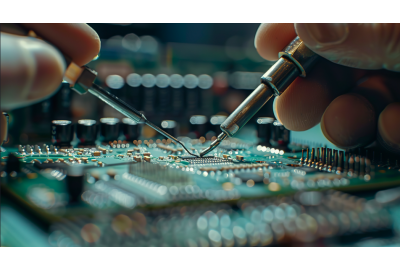

Pneumatic Crimping Tools

Pneumatic crimping tools operate using compressed air to apply consistent force, making them an excellent choice for high-volume, repetitive tasks in settings like manufacturing and assembly lines. These tools are valued for their speed and reliability, as the automated air-powered mechanism reduces manual effort, allowing users to complete large volumes of crimps with minimal fatigue.

The primary advantage of pneumatic crimping tools is their ability to deliver uniform crimps, which ensures consistent quality across tasks and reduces the likelihood of errors compared to manual methods. They are particularly suited for precision work and are often used with smaller connectors and delicate components in industries such as electronics and telecommunications.

However, pneumatic tools do require a steady supply of compressed air, which can be a limitation in fieldwork or remote locations. For optimal performance, consider models with adjustable pressure settings to customise the force based on material and connector type.

Applications of Crimping Tools

They can be used across various industries, each requiring specific applications and tools. Here, we will look at the primary applications of these products in electrical work, the automotive industry, telecommunications, and networking.

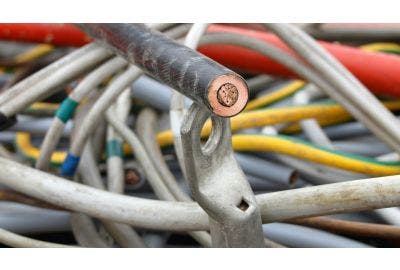

Electrical Work

These are indispensable in electrical work and used to create secure connections in wiring and components.

Common Tasks and Projects

In electrical work, these are used for tasks such as wiring installations, repairing electrical circuits, and connecting cables to terminals and connectors.

Specific Tool Recommendations

For electrical work, handheld and battery powered crimpers are highly recommended.

Handheld crimps are ideal for small-scale tasks, while going with battery powered crimpers offers efficiency for larger projects.

Tips for Effective Crimping in Electrical Work

- Always use the right size of crimping tool and connectors for the job.

- Strip the wire to the correct length before crimping.

- Double-check connections for security and conductivity.

Safety Considerations

- Wear appropriate safety gear, such as gloves and safety glasses.

- Turn off the power before working on electrical circuits.

- Use insulation to prevent electrical shocks.

Automotive Industry

Crimping tools are also widely used in the automotive industry for various electrical and mechanical connections.

Automotive tasks include wiring harness assembly, battery cable connections, and repairing vehicle electrical systems. Hydraulic crimp tools provide the necessary force for heavy-duty connections, while handheld versions are suitable for more delicate tasks.

Tips for Effective Crimping in the Automotive Industry

- Select the appropriate crimping tool for the wire gauge and connector type.

- Make sure the crimped connection is strong enough to withstand vibrations.

- Regularly inspect for wear and tear.

Safety Considerations

- Disconnect the battery before working on the vehicle's electrical systems.

- Use equipment that is specifically designed for automotive use.

- Keep a fire extinguisher nearby in case of electrical fires.

Telecommunications

In telecommunications, crimp tools are essential for creating reliable connections in network cabling and communication systems.

Tasks include crimping connectors onto network cables, assembling communication equipment, and installing telephone systems. Battery-powered crimp tools are preferred in telecommunications for their efficiency in high-volume tasks while ratcheting crimp tools offer the precision required for more delicate or specialised connections. The ratcheting mechanism ensures consistent pressure, which is vital for the secure, high-quality connections needed in telecommunications.

Tips for Effective Crimping in Telecommunications

- Use high-quality connectors for reliable connections.

- Follow industry standards for cable assembly and connector crimping.

- Test the connections with appropriate testing equipment.

Safety Considerations

- Handle cables carefully to avoid damaging the conductors.

- Follow proper procedures to avoid interference and signal loss.

- Keep work areas organised to prevent tripping hazards.

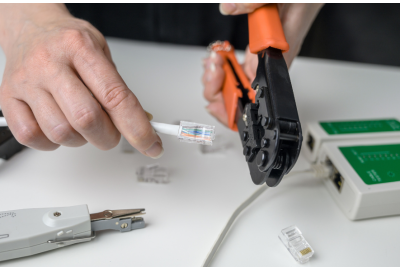

Networking

Networking professionals rely on these for creating connections in data communication systems and network installations.

Tasks involve crimping RJ45 connectors onto Ethernet cables, assembling patch panels and setting up network infrastructure.

Handheld and battery powered crimping tools are commonly used in networking. Handheld is more suitable for small-scale installations, while battery powered offers speed and consistency for larger projects.

Tips for Effective Crimping in Networking

- Cut and strip the cable correctly before crimping.

- Use the right type of crimping tool for the connectors.

- Test the cables for continuity and performance after crimping.

Safety Considerations

- Follow best practices to avoid damaging the cables.

- Ground the network equipment properly.

- Maintain a clean and organised workspace to avoid accidents.

Selecting the right crimping tool involves considering several factors to match your specific needs and applications. Here are the key aspects to keep in mind when purchasing crimping tools.

Factors to Consider When Buying Crimping Tools

Type of Connection

These are also designed for various connection types, such as insulated terminals, non-insulated terminals, and coaxial connectors.

Each type requires a specific crimping method to achieve a secure connection. Using the correct crimping tool for the connection type is important to achieve a reliable and strong bond.

Mismatched appliances can lead to poor connections, which may result in electrical failures or other issues. For example, use a handheld tool for insulated terminals in basic electrical work, while a hydraulic crimping tool is suitable for heavy-duty non-insulated connections in industrial settings.

Using an incorrect tool can cause damage to both the tool and the connector, leading to unreliable connections and increased downtime for repairs.

Compatibility with Connectors

There are various connector types, including cable lugs, bootlace ferrules, butt connectors and coaxial connectors.

Each connector type is designed for specific applications and requires a compatible crimping tool. Using a tool that matches the connectors helps create secure crimps that meet industry standards. This compatibility reduces the risk of connection failure and maintains the integrity of the electrical system.

For example, use a mechanical crimping tool for spade terminals in automotive applications, while a battery-powered crimping tool is ideal for crimping coaxial connectors in telecommunications.

Incompatible appliances and connectors can lead to poor crimps, which can compromise the connection’s reliability and safety.

Ease of Use

The usability of a crimping tool depends on factors such as its weight, grip and design.

Lightweight tools with ergonomic handles reduce fatigue and improve comfort during use. An ergonomic design improves user comfort and reduces the risk of strain injuries, especially during repetitive tasks.

For instance, using a handheld crimp tool with cushioned grips and adjustable handles is user-friendly and suitable for extended use.

When selecting a tool, consider its balance, handle comfort and ease of operation. Always attempt to choose equipment that has features designed to reduce user fatigue.

Durability and Build Quality

Durable materials, such as high-grade steel and reinforced plastics, contribute to the longevity of the product and its ability to withstand regular use. Look for equipment with solid construction, high-quality finishes and positive reviews from other users as indicators of high build quality.

Before purchasing, check for solid construction, high-quality materials and warranties offered by manufacturers as indicators of a durable tool.

Cost

Factors Affecting Tool Pricing

The cost can vary based on factors such as brand, material quality and additional features. High-quality tools may have a higher upfront cost but offer better performance and longevity.

Balancing Cost with Quality

You need to find a balance between cost and quality. Investing in a reliable tool may save money in the long run by reducing the need for replacements and repairs.

Tips for Getting the Best Value for Money

Compare different brands and models, read reviews, and consider the tool’s features and build quality to get good value for your money.

Maintenance and Care of Crimping Tools

Proper care of crimping tools are needed to ensure longevity and consistent performance. Regular upkeep not only extends the lifespan of the tools but also helps prevent unexpected failures that could lead to costly downtime or safety hazards.

By adhering to a few basic maintenance practices, you can keep your crimping tools in optimal condition for years to come.

After each use, it’s essential to clean the tool to remove any debris, dirt, or residue that may have accumulated during the crimping process. This can typically be done using a soft brush or a clean cloth. Ensuring that your tool is free of contaminants helps maintain its performance and prevents wear on the moving parts.

Lubrication is another key maintenance task. The moving parts of crimping tools, particularly those in mechanical and hydraulic models, need to be regularly lubricated to keep them operating smoothly. It’s advised to use a lubricant that is recommended by the manufacturer to avoid any potential damage to the tool. Regular lubrication reduces friction and wear, ensuring that the tool operates efficiently and with minimal resistance.

Inspecting your crimping tools for signs of wear and tear is also vital. Regular inspections allow you to identify issues such as cracks, bends, or other damage that could compromise the tool’s safety and effectiveness. If you notice any significant wear, it’s advised to replace the tool or the affected parts immediately. Continuing to use a damaged tool can lead to unreliable crimps and increase the risk of injury.

Signs of Wear and When to Replace Tools

Recognising the signs of wear in your crimping tools is essential for maintaining their functionality and safety. One of the first indicators that a tool may need replacement is a noticeable decrease in performance. If the tool is no longer crimping as effectively as it once did, or if you notice inconsistencies in the crimps it produces, it may be time for maintenance or replacement. This is particularly useful in professional settings where reliable connections are critical.

Visible damage is another clear sign that a tool should be replaced. Cracks, chips, or any other physical deformations indicate that the tool may no longer be safe to use. Even minor damage can affect the tool’s ability to create secure connections, leading to potential failures in the field.

Additionally, difficulty in operation is a sign that a tool may be nearing the end of its useful life. If the tool becomes hard to operate, feels stiff, or requires more force than usual despite regular lubrication, it’s likely time to consider a replacement. Using a tool that is difficult to operate can lead to inconsistent results and increased user fatigue.

Proper storage is also needed to prevent premature wear. Crimping tools should be stored in a dry, clean environment to avoid rust and corrosion. Using protective cases or tool boxes can further safeguard the tools from physical damage during storage. Avoid exposing them to extreme temperatures, as this can negatively affect their performance and longevity.

By following these maintenance practices and being vigilant about signs of wear, you can ensure that your crimping tools remain in good working order, providing reliable performance and safety in all your projects.

Choosing the right crimping tool is vital for ensuring reliable connections, whether you’re working in electrical, automotive, aerospace, renewable energy, telecommunications or networking. By considering the type of connection, tool compatibility and durability, you can make a well-informed decision. Proper maintenance is also key to extending the life of your tools. Regular cleaning, lubrication, and careful storage will ensure they continue to perform well over time.

For further guidance or to explore Heamar’s range of crimping tools, feel free to contact us. Our team is ready to help you find the perfect tool for your needs.