Understanding wire gauges is essential for anyone involved in electrical wiring, from professionals to DIY enthusiasts. Wire gauge refers to the thickness or diameter of a wire, which directly affects its electrical resistance and current-carrying capacity. Choosing the right gauge is needed for both performance and safety.

Two main systems are commonly used and each system is applied differently across household wiring and industrial uses. This guide covers the differences between those, the importance of accurate gauge measurement, and tips on how to select the right gauge. By better understanding wire gauges, it can help avoid hazards like overheating and equipment damage, and provide efficient energy transfer and longevity in electrical setups.

What Is Wire Gauge and Why Does It Matter?

Wire gauge refers to the standard measurement of a wire’s thickness or diameter, which directly impacts its electrical resistance and current-carrying capacity. Lower gauge numbers represent thicker wires capable of handling higher currents, while higher numbers correspond to thinner wires with lower capacity. Selecting the correct wire gauge is essential to prevent overheating, electrical fires, or equipment damage.

Wire gauge standards, developed in the 19th century, were created to ensure consistency and safety in electrical applications. Today, different systems are used globally, with the American Wire Gauge (AWG) and Standard Wire Gauge (SWG) being the most prominent.

Key Wire Gauge Systems:

- AWG (American Wire Gauge): Common in North America, AWG uses a numerical scale where smaller numbers denote thicker wires. It’s widely employed in residential and commercial wiring.

- SWG (Standard Wire Gauge): Predominantly used in the UK, SWG also uses a numerical scale but has different measurement values. It’s more common in industrial and manufacturing contexts.

Selecting the appropriate gauge depends on factors such as current load, voltage, and distance. Tools, like Go/No Go gauges, can help confirm the right size for your application, ensuring accuracy and safety.

Common Wire Gauge Systems: AWG vs SWG

Both AWG and SWG use numerical scales where smaller numbers represent thicker wires, but it’s important to know that their measurements differ:

| Wire Gauge | AWG Diameter (mm) | SWG Diameter (mm) | Typical Applications |

|---|---|---|---|

| 10 | 2.5883 | 3.251 | Heavy-duty electrical wiring, industrial machinery |

| 11 | 2.3038 | 2.946 | Automotive battery cables, heavy appliances |

| 12 | 2.0523 | 2.642 | Residential wiring for high-current applications |

| 13 | 1.8288 | 2.337 | Medium-duty wiring, loudspeakers, small appliances |

| 14 | 1.6281 | 2.032 | Household electrical wiring, lighting circuits |

| 15 | 1.4503 | 1.829 | Low-current circuits, intercom systems |

| 16 | 1.2903 | 1.626 | Extension cords, small motors, low-power devices |

| 17 | 1.1506 | 1.422 | Electronic devices, internal wiring |

| 18 | 1.0236 | 1.219 | Small household devices, thermostats, doorbells |

| 19 | 0.9119 | 1.016 | Telephone lines, hobby electronics |

| 20 | 0.8128 | 0.914 | Signal cables, low-power circuits, data transmission |

| 21 | 0.7239 | 0.813 | Low-voltage lighting, control wiring |

| 22 | 0.6426 | 0.711 | Audio cables, microcontrollers, general electronics |

| 23 | 0.574 | 0.61 | Sensor wiring, precision equipment |

| 24 | 0.5105 | 0.599 | Computer peripherals, fine wiring for electronics |

| 25 | 0.4547 | 0.508 | Data cables, LED lighting strips |

| 26 | 0.4039 | 0.457 | Instrumentation wiring, medical devices |

| 27 | 0.3607 | 0.417 | Fine electronics, headphones |

| 28 | 0.32 | 0.376 | Ultra-fine wiring, precision instruments |

| 29 | 0.287 | 0.345 | Small transformers, delicate equipment |

| 30 | 0.254 | 0.315 | Miniature electronics, toys, ultra-thin applications |

The key challenge lies in converting between the two systems. For instance, a 10 AWG wire aligns roughly with a 7 SWG wire. Understanding these differences ensures safe and efficient wire selection for various applications.

How to Measure Wire Gauge Accurately

Accurate wire measurement is essential for ensuring safety and functionality in electrical projects. Using the right tools and techniques helps eliminate errors that could lead to equipment failure or safety hazards.

Key Steps for Measuring Wire Gauge

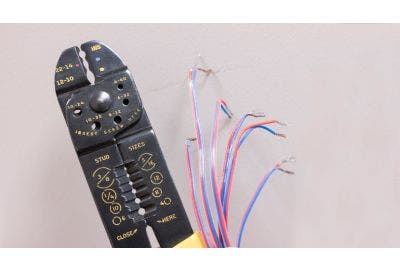

- Prepare the Wire: Strip a small section of insulation with wire strippers to expose the conductor, if necessary.

- Use the Tool: Place the wire into the measuring tool or micrometre, ensuring a snug fit without compression.

- Record Measurements: Note the diameter shown, and take multiple readings to ensure consistency.

- Verify Insulation: Measure insulation thickness if the application demands precision in total wire diameter.

Common Mistakes to Avoid

- Using tools not intended for wire measurement.

- Ignoring insulation thickness when it’s critical for the application.

By following these steps, you can achieve precise wire gauge measurements, ensuring a strong foundation for your project.

Choosing the Right Wire Gauge for Your Application

Selecting the correct wire gauge ensures both safety and optimal performance in electrical installations. Factors like current load, voltage and environmental conditions play a significant role.

Key Considerations for Wire Gauge Selection

- Current Load: Choose a gauge rated to carry the expected current safely. Overloading wires risks overheating and fire hazards.

- Voltage Requirements: Higher voltages may require thicker wires to prevent significant voltage drops, particularly over long distances.

- Length of Wire Run: For extended wiring, thicker wires reduce energy loss and maintain performance.

- Temperature Conditions: In hot environments, wires need to handle heat dissipation effectively, often necessitating thicker gauges.

- Insulation Material: Insulation impacts current capacity, so ensure the wire and its insulation meet project specifications.

- Compliance with Codes: Adhere to local electrical codes and manufacturer guidelines for safety and reliability.

In following these steps, you should be able to confidently select the right wire gauge, ensuring efficiency and long-term safety.

Understanding wire gauges is essential for anyone working with electrical systems, from professionals to DIY enthusiasts. This guide has covered wire gauge basics, the distinctions between these two gauges, how to measure wire gauge accurately, and tips for choosing the right gauge.

Choosing the right gauge contributes to the safety, energy efficiency and durability of electrical systems. With this knowledge, you can avoid potential hazards and ensuring that your wiring projects function as intended.

For more information on electrical tools and gauges or to explore Heamar’s products, contact us.