Getting a smooth, polished finish on your projects often depends on the sanding process. Sanding is essential in woodworking, metalworking, and even DIY home improvement tasks. With the right sanding tools, you can transform a rough surface into a masterpiece, making your finished product look professional and last longer. This guide will take you through everything you need to know about sanding tools, from understanding different types and their specific uses to choosing the right one for your projects and maintaining them properly.

In this guide, we will cover various sanding tools available in the market, including hand sanders, orbital sanders, belt sanders, and detail sanders. You’ll learn about the key features to look for, such as power, speed, and dust collection systems, and get recommendations on popular brands and models. We’ll also cover essential maintenance tips to keep your tools in top condition and safety guidelines to keep your work environment hazard-free.

Whether you are a professional craftsman, a hobbyist, or someone passionate about home improvement, this sanding tools guide aims to help you choose the right equipment to achieve the best results in your projects.

Understanding Sanding Tools

Types of Sanding Tools

Sanding tools come in various forms, each designed for specific tasks and finishes. Understanding the different types can help you choose the best tool for your needs.

- Hand sanders are manual tools that require physical effort to operate. Ideal for small, detailed work where precision is key, they are often used for finishing touches and work well on surfaces that need a light touch.

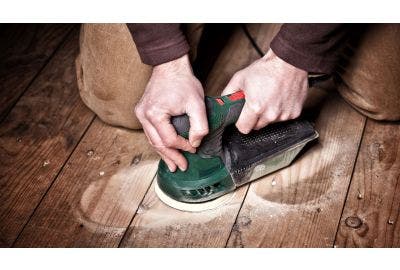

- Orbital sanders are known for their versatility. These electric tools move in small circles or orbits, making them suitable for a wide range of projects, from smoothing rough surfaces to preparing surfaces for painting. Their random motion helps to avoid leaving swirl marks.

- Belt sanders are designed for rapid material removal. They feature a continuous loop of sandpaper, known as a sanding belt, which rotates around two drums. Belt sanders are perfect for large, flat surfaces and can quickly strip paint or varnish.

- Detail sanders are used for intricate sanding tasks. Their small, pointed shape allows them to reach tight corners and delicate areas that other sanders can't, making them ideal for fine finishing work.

- Disc sanders use a rotating disc of sandpaper and are typically mounted on a workbench. They are used for smoothing edges and removing small amounts of material from larger surfaces, common in woodworking and metalworking shops.

When choosing between these types, consider the specific needs of your project. For example, a belt sander might be overkill for fine detail work, while a hand sander could be too slow for a large, rough surface.

Manual vs. Power Sanders

Choosing between manual and power sanders depends on the nature of your work and your preferences.

A manual sander is used for precision work and small projects. These tools are quiet, require no electricity and give you full control over the sanding process. However, they can be tiring to use for large areas and are often time-consuming.

Power Sanders, on the other hand, are electric tools designed for efficiency and speed. They can handle larger surfaces and tougher materials with ease, saving time and reducing physical effort, making them suitable for extensive projects. However, they are louder, require a power source, and can be more challenging to control for fine work.

Choosing the Right Sanding Tool

Project Requirements

Selecting the appropriate sanding tool depends on the specific requirements of your project. Assessing the scope and scale of your work is essential in making an informed choice.

For small, intricate tasks like refinishing furniture or sanding tight corners, detail sanders or hand sanders are ideal. These tools provide the precision needed for delicate work without removing too much material. On the other hand, large-scale projects such as sanding floors or stripping paint from large surfaces demand the power and efficiency of belt sanders or orbital sanders. Orbital sanders, for example, are versatile enough to perform both rough and fine sanding, making them suitable for numerous projects.

When matching the top sanding tool brands to your project needs, consider the following:

- The size of the surface area to be sanded.

- The type of finish required (smooth, rough, detailed).

- The amount of material to be removed.

- Having the right tool not only improves efficiency but also enhances the quality of your work.

Material Considerations

The type of material you are working on significantly influences your choice of sanding tool. Different materials require different approaches to achieve the best finish.

Orbital sanders and belt sanders are excellent for smoothing large wooden surfaces, while detail sanders and hand sanders are suitable for intricate woodwork and finishing touches. For hardwoods, a sander with adjustable speed settings is beneficial to avoid damaging the surface.

Metal requires sanding tools that can handle the material’s hardness and produce a smooth finish. Disc sanders and belt sanders are effective for removing rust or paint and preparing metal surfaces for further treatment. Power sanders with higher motor power are generally preferred for metalworking.

Plastic sanding is advised with tools that won’t generate too much heat, which can melt or deform the material. Orbital sanders with lower speed settings are suitable for plastic, and hand sanders can be used for smaller plastic surfaces to avoid overheating.

Matching the right tool to the material helps you achieve a smooth, professional finish without damaging the material. It also impacts sanding efficiency and finish quality.

Recommendations:

- For wood: Orbital sander for large areas, detail sander for intricate work.

- For metal: Belt sander for large surfaces, disc sander for edges.

- For plastic: Orbital sander on low speed, hand sander for smaller areas.

Features to Look For

Power and Speed

When choosing a sanding tool, power and speed are features to consider. The motor power of a sander directly affects its performance and efficiency. A more powerful motor can handle tougher materials and larger surfaces, making the job quicker and easier.

For most power sanders, motor power is measured in amps or watts. Higher power ratings usually mean the sander can perform more demanding tasks. For example, belt sanders typically have motors ranging from 6 to 12 amps, providing the necessary strength for heavy-duty sanding.

The speed of a sander is often measured in rotations per minute (RPM) or feet per minute (FPM). Adjustable speed settings are beneficial because they allow you to tailor the sander’s performance to the specific task. Lower speeds are ideal for delicate work and fine finishes, while higher speeds are suited for rapid material removal.

Adjustable speed settings are particularly useful when working with different materials. For instance, sanding softwood at a high speed can cause damage, whereas hardwood may require higher speeds for effective sanding.

Recommendations:

- For general use: A sander with variable speed settings offers versatility for different tasks.

- For heavy-duty tasks: Opt for a sander with a higher power rating to handle tougher materials.

Dust Collection Systems

Dust collection is a key feature of the best sanding tools, contributing to cleanliness and health. Efficient dust collection systems help maintain a clean workspace and protect you from inhaling harmful dust particles.

Types of Dust Collection Systems:

- Bag Systems: Many sanders come with attached bags that collect dust as you work. These are simple to use but can fill up quickly, requiring frequent emptying.

- Canister Systems: Some sanders use canisters instead of bags, which can hold more dust and are easier to empty and clean.

- Vacuum Attachments: For more efficient dust collection, some sanders can be connected to a shop vacuum. This method is highly effective, keeping the workspace cleaner for longer periods.

Pros and Cons:

- Bag Systems: Easy to use but need frequent emptying.

- Canister Systems: Larger capacity, easier to clean.

- Vacuum Attachments: Most efficient, but require an additional vacuum.

Maintenance Tips:

- Regularly empty and clean dust bags or canisters to maintain efficiency.

- Ensure the vacuum hose is securely attached to prevent dust leaks.

- Choosing a sander with a good dust collection system not only keeps your workspace clean but also improves your health by reducing dust inhalation.

Popular Brands and Models

When selecting sanding tools, it's essential to consider models that offer reliability, efficiency, and versatility. Mirka is a leading brand that consistently delivers high-performance sanders suitable for various tasks, whether you're working on detailed touch-ups or large-scale projects.

For professionals tackling larger surfaces, the Mirka MIRO 955 Electric Dry Wall Sander stands out. With its extended handle and large 225mm pad, this sander is ideal for quickly smoothing walls and ceilings. It's designed to cover extensive areas efficiently, making it a go-to tool for drywall work.

For those who require the freedom of movement, the Bosch GEX 18V-125 Professional - Cordless Random Orbit Sander offers the convenience of cordless operation without compromising on power. This model is perfect for situations where flexibility is key, allowing users to work in various environments without being restricted by power cords.

Additionally, for intricate work and hard-to-reach areas, the Mirka DEOS Delta 663XCV Electric 110V Orbit Corner Sander is a top contender. Its triangular pad makes it particularly effective for sanding corners, edges, and other detailed areas that larger sanders cannot reach. This tool combines precision with power, making it a valuable addition to any toolkit.

Whether you're a professional craftsman or a dedicated hobbyist, these models from Mirka offer a combination of innovation, performance, and durability. Choosing the right sander from these popular models can significantly enhance the quality and efficiency of your projects.

Maintenance and Care

Cleaning and Storage

Maintaining your equipment through regular cleaning and proper storage can significantly extend its lifespan and keep it working effectively. After each use, you need to clean your tools to remove dust and debris that can accumulate and affect their functionality. For power sanders, use a vacuum or compressed air to clear dust from the motor and other internal components. This helps prevent overheating and keeps the motor running smoothly.

For manual sanders, a simple wipe-down with a damp cloth can remove most dust and dirt. It’s advised to check the sandpaper for any wear and tear and replace it as needed to maintain effective sanding. Keep them in a dry, cool place to avoid moisture damage and rust, especially for metal parts. Use tool boxes or wall-mounted racks to organise your tools, preventing them from being misplaced or damaged. If your sander comes with a dust bag or canister, empty it regularly to maintain efficient dust collection and prevent clogging.

Regular sanding tool maintenance checks can help identify any issues early, keeping your tools in good working condition. By taking these steps, you can prolong the lifespan and reliability of your equipment, making them a worthwhile investment for any project.

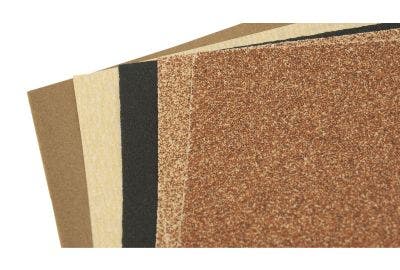

Replacing Sanding Pads

Knowing when and how to replace sanding pads is essential for maintaining effective performance. Signs that your sanding pads need replacement include visible wear, reduced sanding efficiency, and an uneven sanding surface. Using worn-out pads can lead to poor results and damage the material you're working on.

To replace sanding pads, first, make sure the sander is unplugged or powered off. For most sanders, removing the old pad involves simply peeling it off, as they are often attached to hook-and-loop fasteners. Clean the pad holder to remove any residual dust or adhesive before attaching the new pad. Align the new pad carefully to make sure it sits flat and secure.

Choosing the right sanding pads for your specific tool and project is also a major requirement. Different grits are suitable for various tasks, from coarse sanding for material removal to fine sanding for finishing touches. To maximise the lifespan of your sanding pads, store them in a dry place and avoid excessive pressure during use.

Safety Tips

Proper Handling

Proper handling of your tools is essential to prevent accidents and allow for smooth operation. When using manual or power sanders, always maintain a stable work environment. Secure the material you're working on with clamps or a sturdy workbench to prevent it from moving unexpectedly.

For manual sanders, use a firm yet gentle grip to control the tool without applying excessive pressure, which can damage the surface or the tool itself. When operating power sanders, start with a lower speed setting to get a feel for the tool and gradually increase the speed as needed.

Be aware of common hazards such as loose clothing, jewellery and long hair, which can get caught in moving parts. Keep your workspace clean and free of obstructions to avoid tripping or other accidents. Always read the manufacturer's instructions for specific safety guidelines related to your sander model.

Protective Gear

Wearing the appropriate protective gear is required for safe sanding. Safety glasses or goggles protect your eyes from dust and debris, while a dust mask or respirator helps prevent inhalation of harmful particles. For tasks generating a lot of dust, a respirator with a higher filtration rating may be necessary.

Gloves can protect your hands from abrasions and provide a better grip on the tool. However, make sure they fit well to avoid reducing dexterity. Ear protection, such as earplugs or earmuffs, is strongly advised when using power sanders, as prolonged exposure to noise can damage hearing.

Wear long sleeves and trousers to protect your skin from dust and potential splinters. Choosing high-quality protective equipment improves your safety and comfort during sanding projects. Regularly inspect your gear for any signs of wear and replace it as needed to maintain effective protection.

By following these safety tips and using proper handling techniques, you can minimise the risk of accidents and injuries, allowing for a safe and productive working environment.

Selecting the right sanding tool for your project can make a significant difference in achieving a smooth and professional finish. From understanding the various types and their specific uses to maintaining them properly and following essential safety tips, this guide provides the information needed to make informed choices.

Investing in quality improves not only your work's efficiency but also its quality and safety. Apply these tips and guidelines to your sanding projects, and for further assistance or inquiries, feel free to contact us.