Electricians, technicians, engineers, and other professionals working with electrical wiring must ensure they conduct appropriate cable management. The effective organisation of cables is essential when handling a bundle of wires, also known as wire bundles or wire harnesses.

Our guide will help you discover the challenges of wire installations and how to effectively mitigate the risk of wire bundle damage, increasing the safety, performance, and longevity of applications.

Types of Damage to Wire Bundles

Abrasion and Friction

In many industrial and electrical applications, cables are often bundled together or routed through conduits. When these cables rub against each other due to vibrations, movement, or other factors, it can result in friction.

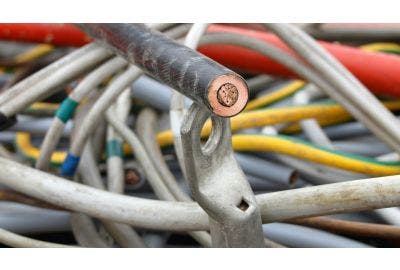

Over time, this continuous cable-to-cable friction can lead to abrasion and wear. The outer insulation of the cables may degrade, exposing the inner conductors and potentially causing short circuits or electrical hazards.

Cable-to-surface friction may also occur in wire bundles.

For example, cables secured to walls, floors, or other surfaces may experience friction as they move or as external forces act upon them.

The constant rubbing of the cable against a surface can gradually wear down its protective insulation or jacket. This can weaken the cable's integrity and expose it to environmental factors or physical damage.

Environmental Factors

Power lines, telecommunications cables, or outdoor extension cords are exposed to various environmental conditions.

Exposure to environmental factors such as moisture, UV radiation, extreme temperature fluctuations, and various weather conditions, including wind, rain, and ice, can significantly deteriorate wire bundles over time.

Moisture can seep into cable insulation and damage the conductors. This can lead to corrosion, short circuits, and reduced insulation resistance.

Cables used in ships and offshore platforms are exposed to saltwater, which can accelerate corrosion.

As mentioned, extreme temperatures can lead to issues with wire bundles.

For example, heat can cause cable insulation to become brittle and degrade, while extreme cold can make it more susceptible to cracking.

Therefore, aircraft wiring must withstand extreme temperatures at high altitudes.

Equally, vehicle wiring faces temperature variations from the scorching heat of summer to freezing winters.

Another environmental factor that can contribute to wire bundle degradation is ultraviolet (UV) radiation.

The sun can cause cables to crack, reducing electrical performance.

Cables affected by UV radiation due to long periods of exposure include those used for solar panels or outdoor surveillance systems.

Mechanical Stress and Strain

Mechanical stress and strain can damage wire bundles, compromising their electrical integrity and functionality.

Below are some factors that can contribute to mechanical stress and strain.

Bending

A wire bent beyond its minimum bend radius can cause deformation and damage its parts.

In the aerospace industry, personnel often route aircraft wiring through tight spaces with sharp corners, which can lead to the overbending of cables during installation.

If the wires are repeatedly bent beyond their specified radius, it can lead to conductor breakage or insulation cracking, resulting in electrical shorts, signal interference, or even complete circuit failure.

Twisting

Twisting refers to the torsional stress applied to a cable. It can lead to the separation of conductors within a cable or cause the insulation to weaken.

Ethernet cables used in networking applications can experience twisting when they are excessively misshapen during installation.

Distorted wires may also occur when office workers repeatedly run over them in chairs.

When cables become twisted, this can disrupt signal integrity and data transmission, leading to network connectivity issues.

Tension

Excessive tension, or pulling force, applied to a wire can stretch, deform, or break it.

In the telecommunications industry, engineers often pull fibre optic cables through conduits during installation. If they apply too much tension, this can cause fibre breakage.

Tension-induced damage can result in signal loss, reduced data transmission rates, and costly repairs.

Best Practices for Reducing Damage to Wire Bundles

1. Provide proper routing and bundling.

Organising and securing wire bundles helps prevent mechanical stress, abrasion, and damage that can lead to electrical shorts, signal interference, or even complete cable failure.

A well-organised cable system makes identifying and accessing specific cables easier for maintenance, repairs, or upgrades, reducing downtime and minimising the risk of errors during work.

Furthermore, properly routed and secured cables reduce the risk of tripping hazards and can prevent accidental contact with sharp edges or hot surfaces, enhancing safety in the workplace.

Lastly, careful routing and bundling help minimise electromagnetic interference (EMI), ensuring signals remain clear, safe, and reliable.

Follow the below tips to ensure correct routing and bundling.

Acquire Appropriate Cables

Choose cables with the appropriate specifications for your application, such as flexibility, insulation type, and shielding, to ensure they can withstand environmental and mechanical conditions.

Carefully Choose Your Route

Route cables away from sharp edges, corners, or rough surfaces that can cause abrasion or cutting of the cable insulation.

Check the Minimum Bend Radius

Follow the manufacturer's recommendations for the minimum bend radius of each cable type.

2. Cable protection solutions.

With the right tools and equipment, you can help mitigate damage, enhancing the protection of your wire bundles.

Below is a list of items to use in your installations as part of your cable protection solutions.

Conduit

- Provides complete protection by enclosing cables in a rigid or flexible tube.

- Resistant to mechanical stress, impact, moisture, and UV radiation.

- A metal conduit offers excellent EMI/RFI shielding.

- Facilitates organised cable routing and management.

Cable Sleeves

- Flexible and expandable, allowing for easy installation and access to cables.

- Provides abrasion resistance and insulation against temperature fluctuations.

- Available in various materials like nylon and polyester for different needs.

Grommets

- Simple solution to protect cables passing through holes.

- Provides a cushioned path for cables to prevent chafing and wear.

Cable Ties and Clips

- Secures and bundles cables together for organisation.

- Available in various sizes and materials for different applications.

- See our range of cable ties and banding straps, which are commonly used in the aerospace industry.

Cable Tray Systems

- Supports and contains cables in elevated pathways, providing easy access for maintenance.

- Suitable for large cable volumes and high-density installations.

- Provides good ventilation.

3. Labelling and Documentation.

Proper labelling and documentation for wire bundles are essential practices in electrical and data cable management, contributing to cable systems' overall efficiency, safety, and reliability.

Below are just a few reasons why documentation is essential for cable management.

Easy Identification

Labels clearly identify cables, indicating their purpose, source, and destination. This simplifies locating and isolating specific cables during maintenance or repairs.

Efficient Replacement

Detailed documentation allows maintenance personnel to quickly assess the type and specifications of cables, making it easier to order replacements when needed.

Reduced Downtime

Faster identification and troubleshooting reduce downtime; technicians can swiftly address issues without extensive searching or guesswork.

Quick Fault Isolation

Properly labelled cables and well-documented systems enable technicians to pinpoint the source of problems, whether a short circuit, signal interference, or a connectivity issue.

Accurate Diagnosis

Detailed documentation helps in diagnosing the root cause of issues, reducing the likelihood of misdiagnosis and unnecessary repairs or replacements.

Minimised Errors

Eliminating confusion and errors during troubleshooting ensures that personnel can resolve issues correctly the first time, preventing recurring problems.

Safe Handling

Labels can include safety information, such as voltage ratings and warnings, which helps prevent mishandling and electrical accidents.

Proper Corrections

Clearly labelled cables reduce the risk of incorrect connections, leading to equipment damage, data loss, or electrical hazards.

Regulatory Compliance

Most industries require proper documentation and labelling to ensure compliance with industry standards and regulations such as those in the electrical, telecommunications, and healthcare sectors.

Audit Trail

Documentation provides an audit trail for cable installations and modifications, ensuring transparency and accountability in compliance with industry regulations.

Scalability

Detailed records of existing cable systems make planning and executing expansions or upgrades easier, ensuring personnel can seamlessly integrate new components.

Maintaining Wire Bundles

Effective Training

Training is crucial in preventing damage to wire bundles and ensuring the safe and reliable operation of electrical and data cable systems.

The process should involve familiarisation with the tools and equipment needed, including using them correctly and safely.

Educating personnel on proper handling and maintenance procedures is essential for several reasons.

- Safety.

- Cable damage.

- Electrical damage.

- To ensure they follow industry best practices for cable installation and routing.

Regular Inspections

Routine inspections are crucial for maintaining the integrity, safety, and reliability of wire bundles and cable systems.

Here's why regular inspections are essential, along with what to look for during these inspections:

- Regular inspections are a form of preventive maintenance. They help detect and address problems before they escalate into more significant issues, reducing the risk of cable failure.

- Identifying and rectifying cable-related hazards, such as exposed conductors or damaged insulation, is essential for personnel safety and preventing electrical accidents.

- Well-maintained cable systems are more reliable, ensuring continuous operation without unexpected interruptions.

Repair and Replacement

Neglecting damaged wires can lead to various consequences, including safety hazards and system failures.

When to Repair or Replace Damaged Wires

- If you notice visible damage to wires, such as exposed conductors, frayed insulation, or physical deformities in the cable jacket, it's essential to address it promptly.

- When you experience electrical problems such as intermittent connections, voltage drops, or circuit disruptions, damaged wires should be considered a potential cause. Investigate and repair or replace any cables contributing to electrical issues.

- Damaged wires pose safety hazards, including the risk of electrical shocks, fires, or accidents.

- Cables exposed to environmental factors like moisture, extreme temperatures, or chemicals are susceptible to degradation. Regular inspections can help identify environmental damage, which personnel should address promptly to prevent further deterioration.

- Over time, cables can experience wear and tear, especially in high-stress or high-flexibility applications. Regular inspections should detect signs of wear, such as cracks or breaks in insulation, which may require repair or replacement.

How to Repair or Replace Damaged Wires

- Begin by assessing the extent of the damage. Determine whether the damage is localised to a specific section or the entire cable needs attention.

- If the damage is localised, consider isolating the affected portion by cutting it out and splicing in a new section of cable. Ensure that splicing is done correctly, following industry standards and guidelines. Spliceline wire connectors can be used to connect two pieces of cable back together, as can a butt connector.

- If connectors or terminations are damaged, inspect them carefully. Loose or corroded connectors should be tightened or replaced. You may need to replace damaged connectors.

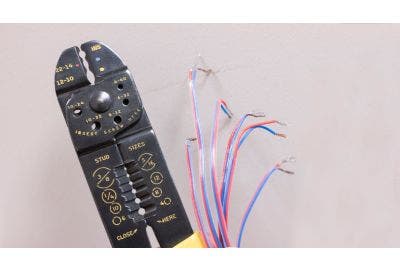

- You will need a wire crimping tool to join wires together or to a terminal, which may require cable lugs.

- Electrical connections require accurate stripping, so use wire strippers to remove the insulation without nicking the wires.

- For cables exposed to environmental damage, consider using cable sleeves, heat shrink tubing, or a protective conduit to shield them from further harm.

- Sometimes, you can repair minor insulation damage with insulating tape or heat shrink tubing designed for electrical applications. However, you should follow this temporary solution with a permanent repair or replacement.

- Keep detailed records of any repairs or replacements, including the date, location, and specifics of the work performed. This documentation is valuable for tracking the maintenance history of the cable system.

Need help with reducing wire bundle damage?

If you need electric wire bundle protection, at Heamar, we supply various wire tools, such as wire cutters and pliers, to help you enhance your cable management solutions.

Contact us if you have any questions regarding our tools.