When it comes to working with wires and cables, many people overlook one critical step, which is stripping the insulation properly, and by that we mean not nicking the conductor. This blog will explain why avoiding such damage is essential and how choosing the right wire stripper can make all the difference, especially when dealing with connectors, insulation, and MIL-SPEC compliant systems.

Understanding Wire and Cable Structure

Before diving into techniques and tools, it's important to understand what makes up a wire or cable. Most electrical wires consist of a metal conductor (more on what a conductor is below), typically copper or aluminium, which is surrounded by an insulating layer that is generally made of plastic or rubber. Cables may include multiple conductors bundled together and shielded for protection against interference. Below is a quick breakdown of what a cable structure could include -

Conductor

This is the central core of a wire and is typically made from copper or aluminium, with copper being favoured for its superior conductivity and flexibility, while aluminium is lighter and used where weight savings are important.

The conductor carries the electrical current and nicking or cutting into the conductor, even slightly, can reduce its ability to carry current efficiently, which can lead to breakage and over-heating over time.

Insulation

Surrounding the conductor is a layer of insulation made from plastic, rubber or fluoropolymer materials like PTFE. Its job is to prevent electrical current from escaping but also protect the conductor from moisture, chemicals and physical abrasion.

Shielding (for cables)

In many cables, especially those used in audio, data or aerospace applications, a shielding layer is included. This can be a foil or braided mesh designed to block electromagnetic interference (EMI) and damaging or removing this shielding can degrade signal quality or increase susceptibility to interference.

Jacket (for multi-conductor cables)

For cables that contain multiple insulated conductors, an outer jacket holds everything together. This is made from tougher materials than insulation (such as PVC or PUR) and provides physical protection, as well as bundling.

What Happens When You Nick a Conductor?

Nicking a conductor might seem like a minor issue, but it can lead to serious consequences. Here's why -

- Electrical Resistance: A nicked conductor has a reduced cross-sectional area, increasing resistance and causing heat build-up, which can lead to fires.

- Mechanical Weakness: Over time, the weakened section can break, especially in environments subject to vibration or movement.

- Poor Connectivity: Damaged conductors may not seat properly in connectors, leading to intermittent faults or complete failure.

Why Proper Wire Stripping Tools Matter

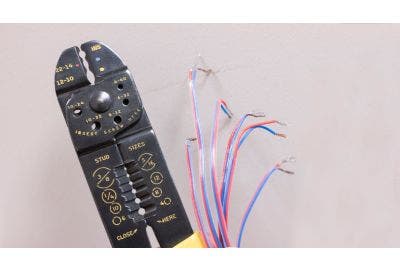

Using a utility knife or electrical scissors might seem convenient, but these tools often lack the precision needed for safe stripping. A dedicated wire stripper, especially one designed to handle specific wire gauges and insulation types, ensures a clean cut without damaging the conductor.

High-quality wire strippers offer:

- Adjustable blades to accommodate various wire sizes/gauges.

- Ergonomic designs to reduce hand fatigue, ensuring the operator can use the wire strippers for longer periods of time.

- Consistent results, which improves safety and reliability.

- Some models feature automatic adjustment for different insulation thicknesses, making them ideal for frequent use on various wire gauges.

The Role of MIL-SPEC Standards in Wire Preparation

MIL-SPEC, short for 'Military Specification', refers to a set of stringent standards developed by the United States Department of Defense to ensure the performance, reliability and safety of materials and components used in military applications. These standards are now widely adopted in many sectors, including aerospace, defence and high-performance industrial sectors where failure is not an option.

More specifically though, when it comes to wire preparation, MIL-SPEC standards dictate precise methods for stripping insulation, crimping terminals and assembling wire harnesses to minimise the risk of electrical faults or mechanical failures.

Some examples of MIL-SPECS that are relevant to wire stripping include -

- MIL-W-5088 (now superseded by SAE-AS50881): Covers the design and installation of aircraft wiring systems and outlines wire routing, protection and termination requirements.

- MIL-DTL-22520: This is the most relevant standard for wire preparation. It governs the use of crimping and stripping tools for electrical connectors and wiring, to ensure they deliver consistent results without damaging the conductor or wire insulation.

There are many more MIL-SPECS available, with the above highlighted just to provide a taste of what they are about. Many MIL-SPEC wire strippers cover a broad range of military specications that are designed to be used on a wide range of wire specifications. Ensure that when you use a wire stripper that the frame and blade are designed for your intended wire stripping project.

Why MIL-SPEC Matters

- Consistency and Reliability: MIL-SPEC procedures ensure that every technician, regardless of location or skill level, follows the same rigorous protocols, which eliminates guesswork and human error.

- Zero Tolerance for Damage: Under MIL-SPEC, even a minor nick or scratch on a conductor is unacceptable. The tools used must be calibrated and approved to strip insulation, which ensure that they won't affect the conductor beneath.

- Environmental Resilience: Military-grade wiring often operates in extreme environments (e.g. aircraft, ships, armoured vehicles). Proper preparation ensures connections withstand vibration, corrosion, temperature extremes and electromagnetic interference.

Although MIL-SPEC protocols were developed for military use, its specifications are used by many commercial aerospace and industrial manufacturers because these specifications enhance reliability and meet quality control benchmarks.

Choosing the Right Wire Stripper for Your Job

When selecting a wire stripper, it is important that you consider the following -

- Wire Gauge Compatibility: Ensure the stripper suits your wire size/s.

- Insulation Type: Match the stripper to plastic, rubber or in some cases, fibre-based insulation.

- Work Volume: For large projects, consider automatic or self-adjusting strippers as they will enhance the comfort of the operator over longer periods of time.

- Wire Specifications: Ensure that the blade you are using on your wire stripper is stated for use on the specication of wire you are stripping. For example 5 MIL Kapton could be used with any of the following wire strippers, which are all stated for use on this spec -

Stripping wire may seem like a small task, but doing it incorrectly can lead to significant issues. High-quality wire strippers like those manufactured by IDEAL, DMC and Klauke can help you protect the integrity of your cables and ensure safe, long-lasting electrical connections. So whether you're handling simple DIY projects at home or working with intricate MIL-SPEC systems, investing in the right tools will pay off. Get in contact with us today if you need more information on which wire stripper is most suitable for your task.