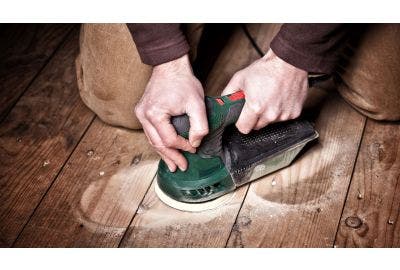

Whether you're a weekend DIY warrior or a seasoned woodworking professional, the right sander is key to achieving that perfect, smooth finish. Among the top choices are the orbital sander and the sheet sander, each with its distinct strengths and ideal applications. Understanding these differences is crucial in selecting the tool that best matches your projects and expertise.

This article looks at key features, performance aspects, and best use cases of orbital vs sheet sanders, helping you determine which tool is the best fit for your needs.

What is an Orbital Sander?

An orbital sander is a power tool typically used for sanding wood, as well as metals and plastics. It moves in a simple circular motion, unlike the random orbit sander, which moves both in an orbital and random circular motion. This distinction reduces the chance of creating swirl marks from the sanding pad, but traditional orbital sanders (which move in fixed circular paths) can sometimes leave marks if not used carefully.

Orbital sanders excel in tasks like the final stages of sanding, where a smooth finish is needed, such as sanding furniture, cabinetry, and other woodworking projects and they are particularly well-suited for smoothing surfaces, rounding edges, and working on curved or irregular shapes.

Pros:

- Minimises swirl marks for a cleaner finish.

- Offers easy control, even on curved or uneven surfaces.

- Excels in detailed finishing tasks across various materials.

Cons:

- Less effective for heavy material removal.

- Slower when working on large, flat surfaces.

What is a Sheet Sander?

A sheet sander, often referred to as a finishing sander, operates with a straightforward back-and-forth linear motion. Unlike the circular motion of an orbital sander, the sheet sander’s straight-line movement makes it particularly effective on large, flat surfaces such as doors, tabletops, and panels. This sander is the go-to choice when you need to quickly smooth and prep surfaces for finishing.

Sheet sanders are effective for smoothing large areas and preparing surfaces for painting or staining, they use standard-sized sandpaper sheets, which makes them cost-effective and convenient for various projects.

Pros:

- Excellent for sanding large, flat surfaces.

- More affordable and easier to maintain.

- Works well for preparing surfaces for finishing.

Cons:

- Can leave visible sanding marks if not used carefully.

- Less versatile on curved or intricate surfaces.

Design and Functionality

Orbital sanders can range in size from compact, ergonomic models designed for smaller tasks to larger, more industrial versions built for heavy-duty work. Their sanding pads, often attached with a hook-and-loop system, allow for quick disc changes.

However, the size and weight of these tools vary, with some larger models being less suitable for delicate, detailed work compared to their smaller counterparts. This design enhances manoeuvrability, especially on curved or intricate surfaces, providing greater precision.

In contrast, sheet sanders are larger and more robust, with rectangular pads that cover a broader area at once. Sandpaper attachment usually comes with clamps or clips, offering a secure but less swift changeover.

In terms of noise and vibration (read our guide on hand-arm vibration), orbital sanders tend to be quieter and produce less vibration, making them more comfortable for prolonged use - sheet sanders, however, can be louder and more prone to vibration, which may cause hand fatigue during extended projects.

Power and Performance

Orbital sanders typically come equipped with motors ranging between 2.4 to 3 amps, delivering ample power for finishing tasks. This power, combined with the random orbital motion, ensures smooth and even sanding, reducing the risk of gouging or over-sanding the material. Sheet sanders, on the other hand, often feature motors between 2 to 2.5 amps. While slightly less powerful, these sanders are well-suited for lighter tasks like smoothing large, flat surfaces, though they may struggle with tougher materials or more demanding jobs.

The speed settings on orbital sanders often allow for more precise control, enabling users to adjust the speed based on the material and the desired finish. Sheet sanders generally offer less flexibility, with fixed speed settings that may limit their versatility.

Sanding Efficiency

Orbital sanders excel in fine, detailed work, particularly when dealing with curved or irregular surfaces where precision is key. Their smaller, circular pads may require more time to cover large areas, but they achieve a superior finish with minimal effort. Conversely, sheet sanders, with their larger rectangular pads, are designed for efficiency in covering large areas quickly. They are particularly effective when preparing surfaces for painting or staining, where achieving a perfectly smooth finish may be less critical.

Dust Collection and Maintenance

Effective dust collection is essential for maintaining a clean workspace and protecting the user’s health. Both orbital and sheet sanders typically come with built-in dust collection systems, although the efficiency of these systems can vary.

Orbital sanders are often equipped with advanced dust collection systems, including features like sealed switches and dust-sealed bearings. These mechanisms not only improve the efficiency of dust capture, making them ideal for indoor use but also contribute to the longevity of the tool by protecting internal components from dust damage.

In contrast, while sheet sanders also include dust collection options such as bags or canisters, they may not be as efficient in capturing fine particles. However, their simpler design often translates to easier maintenance and fewer mechanical issues.

Versatility and Applications

Orbital sanders have the edge in versatility due to their ability to handle a wide range of tasks. They can be used for everything from rough sanding to fine finishing, making them a popular choice for both DIY enthusiasts and professionals. Their adaptability to different materials, including wood, metal, and plastic, further improves their appeal.

Sheet sanders, while more specialised, are excellent for tasks that require a smooth, even finish on large, flat surfaces. They are particularly well-suited for woodworking projects where the goal is to create a uniform surface ready for painting or staining.

Cost and Value

Sheet sanders are generally more affordable, depending on the brand and features. Their lower price point, combined with the cost-effectiveness of standard-sized sandpaper, makes them a good value for those who primarily work on flat surfaces.

Orbital sanders, while slightly more expensive, offer better long-term value due to their versatility and superior performance. For users who require a tool that can handle various tasks with precision, the investment in an orbital sander is often worthwhile.

Ultimately, the right sander for your projects depends on your specific needs and the tasks you most frequently tackle. Whether you need the precision and versatility of an orbital sander or the straightforward efficiency of a sheet sander, choosing the right tool can make all the difference. For personalised advice or to explore our extensive range of sanders, don’t hesitate to contact us. Let us help you find the perfect sander to elevate your woodworking or DIY projects.