A torque wrench isn’t just another tool in the box, it’s one of the most important when you’re tightening fasteners that need to be just right. Whether you're working on a car, machine or piece of equipment, the last thing you want is a loose bolt or a snapped one, which is where correct torque really matters.

But here’s the thing, over time, even the best torque wrenches start to lose their edge. To keep yours accurate, you need to calibrate it regularly, otherwise, it could give you the wrong reading without you even realising.

In this guide, we’ll explain how you can check and calibrate your torque wrench at home, when to do it, and what to watch out for, all without overcomplicating things.

What Is A Torque Wrench?

Let’s keep it simple – a torque wrench helps you tighten nuts and bolts to a specific force. That matters because too much or too little torque can easily lead to parts breaking, shifting or failing altogether.

Whether you're working on heavy machinery, vehicles or anything where safety counts, torque accuracy is something you can’t afford to get wrong. This is where torque wrenches earn their keep by giving you a repeatable, controlled way to tighten fasteners.

There are various types of torque wrenches available, such as:

Each tool has its own strengths. Preset models are usually locked to one value, which is great for repeat work. Adjustable versions let you set a different torque each time. Dial and digital ones display torque levels as you work, either with a needle or a screen.

Whichever type you use, one thing stays the same: calibration is key if you want to trust your readings.

How to Tell if Your Torque Wrench Needs Calibration

You might not always notice your torque wrench is off, but over time, accuracy tends to drift. Here’s how you can spot when it’s time to calibrate:

- It doesn’t click at the expected point – especially if you're sure you’ve reached the set torque.

- You’ve dropped it – even a short fall can knock internal parts out of line.

- It’s been a while – over 12 months or more than 5,000 uses? Then calibration is due.

- You've had it repaired – dismantling the tool means the calibration’s likely gone.

- Torque readings vary – if you're seeing inconsistent results across similar jobs, it’s worth checking.

If any of these sound familiar, don’t guess, get it checked or recalibrated. Relying on a faulty reading isn’t just inconvenient, it could end up dangerous.

How Often Should A Torque Wrench Be Calibrated?

A torque wrench needs regular calibration but isn’t set in stone, it depends on how you use it, where and how it's stored. although regular checks help avoid guesswork.

Here’s a quick look at what affects calibration needs:

| Factor | What it Means |

| Usage Frequency | Daily users should calibrate more regularly than occasional users. |

| Torque Load | Staying under 80% of its max range helps – overloading speeds up drift. |

| Storage Conditions | Always release it to the lowest setting if storing for more than a few weeks. |

| Temperature Exposure | Heat can expand metal; cold can contract it but both affect readings. |

| Post-Repair Handling | Always recalibrate after internal parts have been touched or replaced. |

As a general rule of thumb, recalibrate every 5,000 clicks or once a year, whichever comes first.

Keeping on top of it doesn’t take much and it can save a lot of hassle, especially when accuracy matters most.

Calibrating A Torque Wrench

While a professional can calibrate a torque wrench using torque calibration tools like a torque sensor or torque analyser, you can also perform the calibration yourself at home with a bit of patience, the right kit and some careful handling. Here’s a simple way to check and adjust it yourself:

What You'll Need:

- Torque wrench

- Tape measure

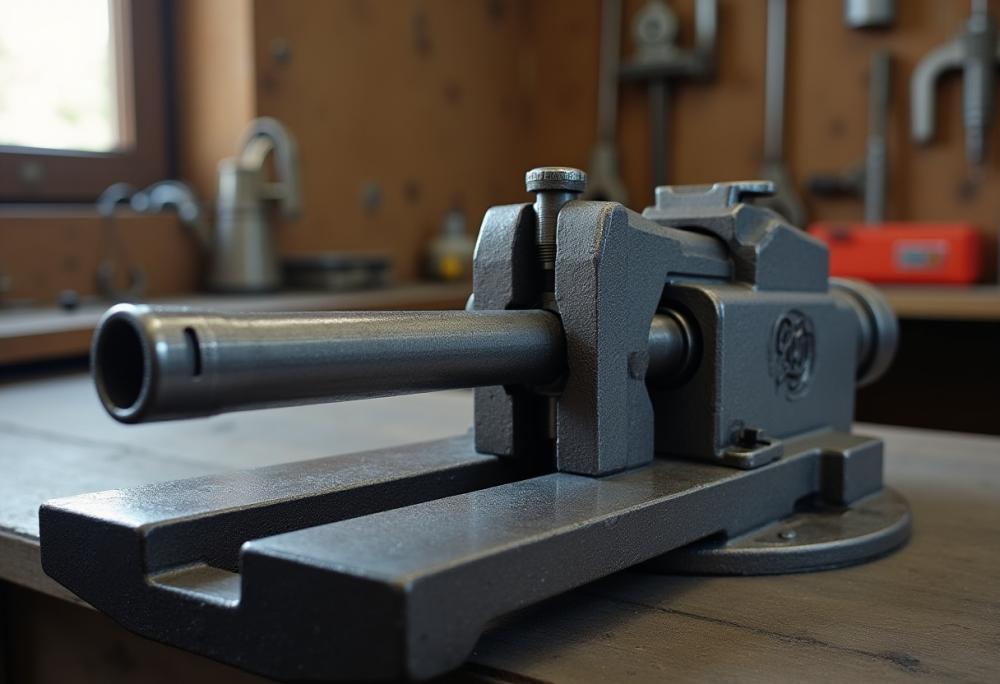

- Bench vice

- 20 lb (9.07kg) weight

- Safety shoes

- Pen and paper

- Piece of string/rope

Step 1: Measure the Handle Length

Use your tape measure to find the distance (in whole inches) from the square drive (where the socket attaches) to the point on the handle where your hand naturally grips. Mark this spot and jot the measurement down.

Step 2: Calculate the Target Torque

Multiply that measurement (in inches) by 20 lb (the weight you’ll be using). Then divide by 12 to convert it into foot-pounds (ft-lbf).

Example:

18 inches × 20 lb = 360

360 ÷ 12 = 30 ft-lbf

Step 3: Set Up Your Work Area

Clamp the square drive into your bench vice, making sure only the drive is held, not the whole wrench body. Position it horizontally with the handle sticking out.

Step 4: Perform the Test

Set your torque wrench to the calculated setting (e.g. 30 ft-lbf). Tie your rope to the marked spot on the handle and carefully hang the weight from it. The rope should be vertical and mustn’t touch the ground or slide along the handle.

If the wrench doesn’t click, you’ll need to adjust it.

Step 5: Adjust the Wrench

Most models have a screw in the handle for fine-tuning. Turn it slightly clockwise and repeat the test. Remove the weight before each new attempt, don’t just slide it up and down.

Once it clicks consistently, gently back off the adjustment until it just stops clicking. This helps pinpoint the sweet spot without overdoing it.

If you can’t get it to respond properly, your wrench might need professional attention.

Safety Tips for DIY Calibration

Calibrating a torque wrench at home is doable but safety still matters. Here’s how to stay on the safe side:

- Wear safety shoes – that 20 lb weight can do real damage if it drops.

- Clear your workspace – keep the floor free of tools or clutter that could trip you.

- Double-check your vice – the wrench should be held firmly by the square drive only.

- Never leave the weight hanging – always lift and reposition it between tests.

- Avoid leaning under the wrench – if it slips, it’ll swing.

If anything feels unstable, stop and reassess. Accuracy’s important, but not at the cost of your toes.

Click vs Digital: Does Type Affect Calibration?

Not all torque wrenches behave the same way when it comes to staying accurate. Here’s what you need to know:

Click-type torque wrenches (including both preset and adjustable) rely on mechanical springs. Over time, those springs weaken, especially if left tensioned, so they usually need calibrating more often.

Digital torque wrenches, on the other hand, use electronic sensors. They’re typically more stable over time but can lose accuracy if dropped, exposed to moisture or strong magnets. Some models also allow electronic recalibration or digital resets.

Regardless of type, regular checks still matter. Just because it’s digital doesn’t mean it’s immune to drift. If you’re using it professionally, it’s wise to stick to the same recalibration schedule across all models and log it, too.

Wrap-Up & Ongoing Care Tips

Keeping your torque wrench accurate isn’t just a box-ticking exercise; it’s a small job that protects your work, your tools and your safety. Regular calibration helps you avoid guesswork and keeps everything working just as it should.

To get the most from your wrench:

- Always release the tension after use (set it back to the lowest setting).

- Store it somewhere dry and moderate in temperature.

- Log each calibration, whether DIY or professional, so you’re never left wondering.

A few habits go a long way. And when your wrench starts to feel “off,” trust your gut because it's better to check now than regret it later.