Choosing the right cable cutter is essential for any professional or DIY enthusiast working on electrical, automotive, or construction tasks. Using the right tool for the wire gauge helps with the efficiency, safety, and longevity of the cutter. The wire gauge—its thickness and size—determines the type of cutter needed, as different gauges require varying amounts of force and specific cutter strengths. By understanding this, you can select the most suitable cutter to perform precise cuts while extending the tool’s lifespan.

This article will help you identify the best cable cutter for different wire gauges, make sure you have the right tool for the job, and improve both cable cutter safety and efficiency in your work.

Understanding Wire Gauges and Their Importance

Wire gauge refers to the thickness of a wire and plays a significant role in choosing the right cutting tool. Measured in American Wire Gauge (AWG) or Standard Wire Gauge (SWG), the gauge number is inversely proportional to the thickness of the wire. Thicker wires have lower gauge numbers, while thinner wires have higher gauge numbers.

Knowing the wire gauge is essential when selecting a cable cutter, as the cutting effort, tool performance, and durability are all influenced by the wire’s thickness. For thicker wires, stronger, more robust cutters are necessary. Thinner wires, on the other hand, require lighter electrical tools. This understanding of wire gauge and cutter compatibility leads to more efficient wire cutting, reduces strain on the tool, and performs effectively over time.

The table below helps to highlight this.

| Wire Gauge | AWG Diameter (mm) | SWG Diameter (mm) | Typical Applications |

|---|---|---|---|

| 10 | 2.5883 | 3.251 | Heavy-duty electrical wiring, industrial machinery |

| 11 | 2.3038 | 2.946 | Automotive battery cables, heavy appliances |

| 12 | 2.0523 | 2.642 | Residential wiring for high-current applications |

| 13 | 1.8288 | 2.337 | Medium-duty wiring, loudspeakers, small appliances |

| 14 | 1.6281 | 2.032 | Household electrical wiring, lighting circuits |

| 15 | 1.4503 | 1.829 | Low-current circuits, intercom systems |

| 16 | 1.2903 | 1.626 | Extension cords, small motors, low-power devices |

| 17 | 1.1506 | 1.422 | Electronic devices, internal wiring |

| 18 | 1.0236 | 1.219 | Small household devices, thermostats, doorbells |

| 19 | 0.9119 | 1.016 | Telephone lines, hobby electronics |

| 20 | 0.8128 | 0.914 | Signal cables, low-power circuits, data transmission |

| 21 | 0.7239 | 0.813 | Low-voltage lighting, control wiring |

| 22 | 0.6426 | 0.711 | Audio cables, microcontrollers, general electronics |

| 23 | 0.574 | 0.61 | Sensor wiring, precision equipment |

| 24 | 0.5105 | 0.599 | Computer peripherals, fine wiring for electronics |

| 25 | 0.4547 | 0.508 | Data cables, LED lighting strips |

| 26 | 0.4039 | 0.457 | Instrumentation wiring, medical devices |

| 27 | 0.3607 | 0.417 | Fine electronics, headphones |

| 28 | 0.32 | 0.376 | Ultra-fine wiring, precision instruments |

| 29 | 0.287 | 0.345 | Small transformers, delicate equipment |

| 30 | 0.254 | 0.315 | Miniature electronics, toys, ultra-thin applications |

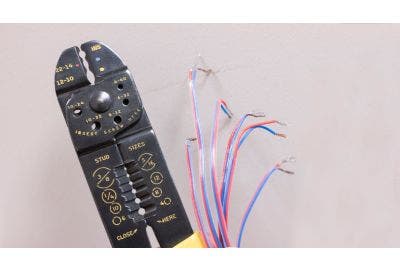

Types of Cable Cutters and Their Applications

There are several types of cable cutters, each designed for specific tasks and wire gauges. Manual cable cutting is ideal for light-duty tasks and smaller gauge wires. These cutters are easy to use but may require more force on thicker wires.

Ratcheting cable cutters, which use a ratchet mechanism, reduce the effort needed to cut. They are particularly useful for larger gauge wires, providing more control and ease when cutting through tougher materials.

Hydraulic cable cutters, best suited for industrial tasks, use hydraulic pressure to cut through the thickest wires with minimal physical effort, making them ideal for heavy-duty applications.

Choosing the right type depends on the wire gauge and the task at hand. Manual cutters suffice for wire-cutting applications for small jobs while ratcheting and hydraulic cutters are better for larger tasks.

Matching Cable Cutter Types to Wire Gauge Sizes

Selecting the correct cutter for each wire gauge delivers precise cuts and prolongs the tool’s lifespan. For smaller gauge wires, manual cutters are typically sufficient as they require less force. These cutters are perfect for light electrical work and DIY tasks.

For medium-gauge wires, ratcheting cutters are recommended. They provide extra leverage, reducing strain while cutting through thicker wires. These cutters are excellent for automotive and moderate electrical work.

For larger gauge wires, hydraulic cutters are necessary. These cutters generate the power required to cut through heavy-duty cables without causing strain. They are ideal for construction and industrial environments where thick cables are commonly used.

By matching the cutter type with the wire gauge, you provide safe, efficient cutting while reducing wear on both the tool and the wire.

Features to Look for in a Cable Cutter

When selecting a cable cutter, look for a tool that offers both performance and comfort. Cutting capacity is one of the most important factors to consider. Strong blades provide clean cuts and help extend the tool’s life, particularly for thicker wires. Ergonomics also matter, especially if you’re using the cutter frequently. Look for cutters with ergonomic handles to reduce hand strain and improve comfort, especially for prolonged use.

Safety features are also needed, particularly for electrical work. Choose cutters with insulated handles to protect against electric shocks. Additionally, features like blade locks and rust-resistant coatings can improve the cutter’s performance and longevity.

Common Mistakes to Avoid When Selecting a Cable Cutter

Several mistakes can affect the effectiveness and safety of a cable cutter. One common error is choosing a cutter that isn't compatible with the wire gauge. Using the wrong size cutter can result in poor cuts and strain on the tool.

Neglecting ergonomic features can lead to hand fatigue, especially during extended use. Additionally, not considering insulation for electrical tasks can pose electrocution risks. It’s best to select a cutter with the appropriate features for your work environment. Avoiding these mistakes will help make sure that your cutter performs effectively and safely, increasing both the quality of your work and the longevity of the tool.

Safety Tips for Using Cable Cutters on Different Wire Gauges

Safety is key when using cable cutters. Before cutting any wires, particularly in electrical work, ensure that the power is turned off, and check for any remaining current. This precaution helps avoid the risk of electric shock.

Always wear protective gear such as gloves and safety goggles. Gloves improve grip and protect your hands from sharp edges, while goggles protect your eyes from flying debris. Provide a firm grip on the handles and apply steady pressure for a clean cut. Lastly, regular maintenance is vital. Inspect your cutter for wear and perform necessary maintenance to keep the tool functioning safely.

How to Maintain and Care for Your Cable Cutter

Proper maintenance means that your cable cutter stays in top condition.

Clean your cutter after every use to remove dirt, grease, and metal shavings. Regular cleaning prevents rust and buildup, which can impair performance.

Check the blades for damage or dullness, and replace them when needed. Proper storage is also required—store your cutter in a dry, safe place to avoid rust. Lubricate the pivot points to provide smooth operation and reduce wear.

Routine care will help keep your cutter safe, efficient, and reliable for long-term use.

Choosing the Right Cable Cutter for Specific Applications

Different tasks require different cable cutters. For electrical work, manual cutters with insulated handles are sufficient for smaller wires, while ratcheting cutters are better for automotive tasks with moderate wire gauges. In industrial or construction settings, hydraulic cutters are necessary for heavy-duty cables. For DIY enthusiasts, a versatile, high-quality manual or ratcheting cutter can cover most household and small project needs, balancing performance and affordability.

On the other hand, professionals in fields like construction or automotive work may require a range of cutters for different wire gauges and applications. Investing in multiple tools, including hydraulic cutters for heavy-duty jobs, means readiness for various tasks, and improving efficiency and safety on the job.

Investing in a quality cutter for the specific job gives a positive performance. For professionals, having multiple cutters for different tasks provides versatility, while DIY enthusiasts may find a single, high-quality tool sufficient for most tasks.

Choosing the right cable cutter is essential to achieving safe, efficient cuts while prolonging the tool’s lifespan. Understanding the wire gauge and selecting the appropriate cutter supports optimal performance and reduces wear. Whether you’re working on electrical, automotive, or construction tasks, selecting the right cutter improves safety and efficiency.

For a wide selection of cable cutters suited to various wire gauges and applications, explore Heamar’s product range or contact us for more information.