With the numerous different varieties of cutters on offer, as well as the range of brands that sell them, making sure you choose the correct cutter for your needs can sometimes be a struggle.

At Heamar, as well as providing specialist tooling solutions, we also offer informed decisions around the tooling technology, applications and relevant standards you need. We’ve put together this complete guide to cutters to help you out and ensure you choose the correct tool for the job.

What are Cutters?

Cutters are a type of hand tool which, as the name suggests, are used to cut different materials. A standard pair of cutters is comprised of two levers that are fixed together at a point located closer to one end of the tool than the other. The shorter portion from the fulcrum are the jaws of the cutter and the longer portion from the fulcrum is the handles of the cutter.

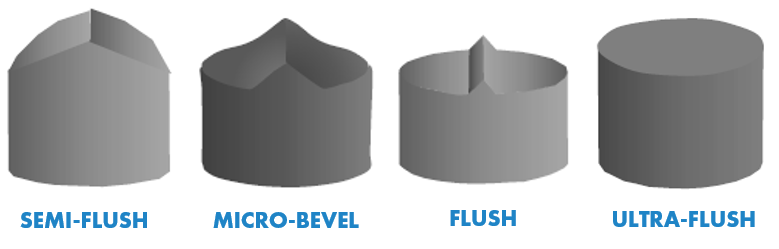

Types of Cutting Edges

When using cutters, each cut type leaves a different shape behind. The more professional tools leave a flusher cut and the lower range tools leave pinches of varying sizes.

The following are the most popular types of cutting edges -

- Semi-Flush – this type of cut leaves a large lead-end shaped like a pyramid. It is most suitable for general electrical or hobby cutting.

- Micro-Bevel – this type of cut leaves a pinch in the leads that have been cut. The main advantage of this type of cut is that it has an extremely wide cutting range for a variety of uses.

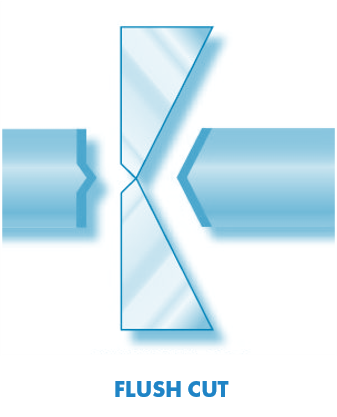

- Flush – this type of cut leaves a small pinch in the leads. This finish is perfect for use when the specifications are tighter.

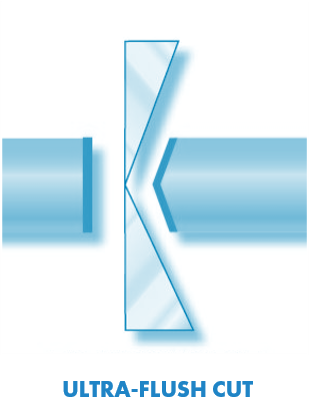

- Ultra-Flush – this type of cut does not leave a pinch at all but has a more limited cutting range. However, there is a greater possibility of damage if this type of cut is misused. This finish is perfect for close tolerance electronics or medical devices.

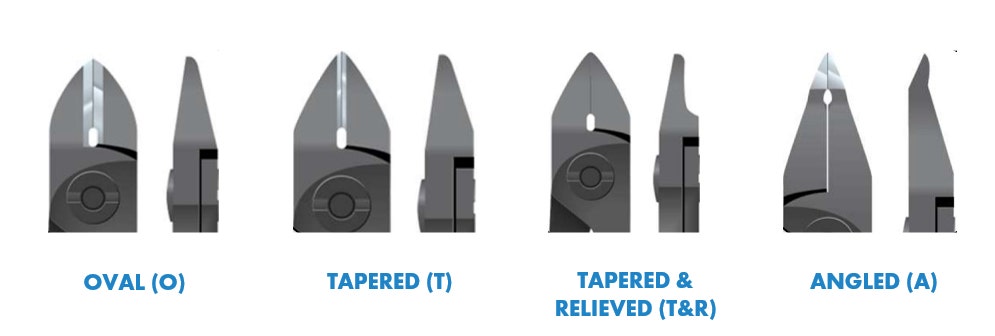

Types of Cutter Head Shapes

- Oval (O) Shaped – this type of cutter head shape combines both strength and flexibility. It can easily withstand and distribute the impact of cutting. Cutters with this head shape can be used for a wide variety of applications.

- Tapered (T) Shaped – this type of cutter head shape allows for use with a broad range of tasks. It has excellent maneuverability, whilst also having a great tool life.

- Tapered & Relieved (T & R) Shaped – this type of cutter head shape is the smallest of the standard cutting heads. The minimal profile and smaller cutting capacity offers maximum accessibility to very limited spaces.

- Angled (A) Shaped – this type of cutter head shape is also known as 'oblique'. It is suitable for tasks with very difficult to access areas, such as under and between low profile components.

Types of Cutter Finishes

There are a wide variety of different types of cutters with different finishes available from numerous different brands. Different types of cutter finishes are more suitable for certain types of applications, so it is important to choose the right pair for your job.

The following are the most popular types of cutter finishes -

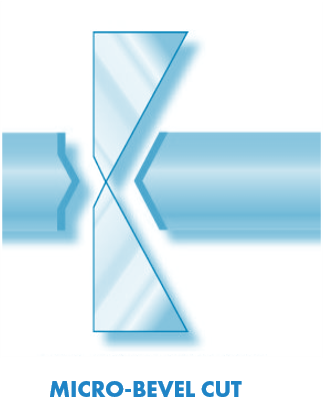

Micro Bevel

This type of finish is ideal for hobbyist jewellery makers, DIY, low tolerance electronics and general purpose. Micro Bevel finishes leaves a large pinch on materials and so would be more suitable for lower end applications where the tolerances are not an issue.

Flush

This type of finish is ideal for motorsport harness production and high-end electricals. Flush finishes offer a slicker finish on the wire that only leaves a small pinch in comparison to a Micro Bevel finish. It is better for applications with slightly higher tolerances, such as jewellery makers looking for a more professional finish than they would get with a Micro Bevel.

Ultra Flush

This type of finish is perfect for MRO harnesses, aerospace applications and high-end jewellery making. Ultra Flush finishes are ideal for use in industries that have the highest tolerances and require high precision tools. This type of finish provides a more professional cut than the Flush and Micro Bevel finishes.

Heamar sell a variety of different cutters, pliers and other hand tools to suit a variety of applications from brands including Lindstrom, Tronex and Xuron.