When it comes to sanding, using the wrong tool can waste hours and lead to poor results. While drywall sanders and orbital sanders might seem interchangeable at first glance, they’re designed for entirely different tasks. Understanding how these tools function and where they’re best suited can save you time, effort, and money.

This guide will cut through the confusion, comparing drywall sanders and orbital sanders in terms of functionality, features, and the tasks they’re best suited for. By breaking down key factors—like dust collection, power sources, and costs—you’ll have all the information needed to choose the tool that fits your project perfectly.

What is a Drywall Sander?

A drywall sander is a tool built for one main job—preparing walls and ceilings after drywall installation. It’s designed to smooth out any joint compound, filler and imperfections, leaving a flat, even surface ready for paint or wallpaper. If you’re working on large areas, like an entire room or a tall ceiling, a drywall sander is essential to get the job done efficiently.

There are three common types of drywall sanders:

- Manual sanders: Handheld tools with a sanding block—useful for small touch-ups or tight corners.

- Pole sanders: These have an extendable handle to reach high walls and ceilings without a ladder.

- Powered sanders: These are equipped with motorised sanding heads, often featuring a vacuum attachment to minimise dust.

Key features of powered drywall sanders include adjustable heads, which make sanding at different angles easier, and extendable handles for tackling hard-to-reach spots. If you’re planning to sand a lot of drywall or work on ceilings, these features will save you significant time and effort compared to manual options.

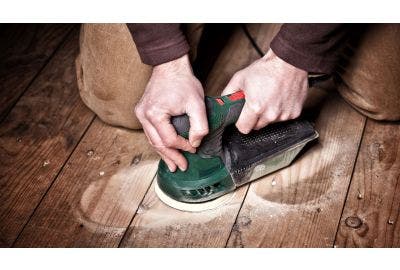

What is an Orbital Sander?

An orbital sander is a compact, versatile tool designed for fine sanding and finishing work. Unlike drywall sanders, which focus on large surfaces, orbital sanders are better suited to smaller, detailed projects like preparing wooden furniture or smoothing cabinet doors.

These tools work by moving a rectangular or circular sanding pad in a rapid, circular motion. This motion ensures a smooth surface without leaving visible patterns or grooves, making it ideal for precision work.

A popular variation is the random orbital sander, which adds an elliptical movement to the circular motion. This feature reduces the chance of swirl marks and delivers an even finer finish, making it a go-to option for tasks requiring a flawless result.

Orbital sanders are lightweight and easy to handle, making them a staple for DIYers and professionals alike. Whether you’re sanding between coats of paint or refinishing a coffee table, this tool provides the control and finesse needed for detailed projects.

Primary Uses

The key difference between drywall sanders and orbital sanders lies in the type of work they’re built for. Drywall sanders are specifically designed for large, flat surfaces, such as walls and ceilings, while orbital sanders excel at more detailed and precise tasks.

- When to Use a Drywall Sander:

If you’re smoothing out joint compound after drywall installation or preparing an entire wall for painting, a drywall sander is the right choice. These tools can cover large areas quickly, and powered models often include features like extendable handles to make ceiling work more manageable. For example, sanding a high ceiling without a drywall sander would take much longer and result in uneven surfaces. - When to Use an Orbital Sander:

Orbital sanders are ideal for smaller, detailed jobs, such as preparing furniture, smoothing woodwork or refinishing cabinetry. Their lightweight design allows for precision sanding, which is particularly useful in corners or for intricate pieces. For instance, an orbital sander can be used to sand the edges of a wooden chair or to smooth a tabletop before applying a finish.

Important Note: Using these tools outside of their intended purposes can lead to frustration and poor results. For example, attempting to sand a large wall with an orbital sander would take much longer and create uneven patterns. Similarly, using a drywall sander on small, detailed surfaces would likely damage the material or leave an uneven finish.

Dust Collection

Sanding can produce a significant amount of fine dust, which not only creates a mess but can also pose health risks if inhaled. Both drywall sanders and orbital sanders offer dust collection features, but the systems differ in efficiency and design.

- Drywall Sanders:

Most powered drywall sanders are equipped with built-in dust extraction systems. These can connect directly to a dust extractor or include an attached dust bag to capture debris as you work. This is particularly important for drywall sanding, where the fine dust from joint compound can easily spread throughout a room. A quality dust collection system not only keeps the workspace cleaner but also reduces the need for extensive cleanup afterward. - Orbital Sanders:

Orbital sanders typically include smaller dust collection systems, such as integrated dust bags or ports for attaching a vacuum. While effective for woodworking tasks, these systems are less suited for handling the volume of dust produced by sanding drywall. For smaller, detailed projects, however, an orbital sander's dust collection system is usually sufficient.

Why It Matters: Working in a clean environment improves visibility and precision while reducing respiratory hazards. If your project involves extensive sanding, especially in enclosed spaces, investing in a tool with a strong dust collection system will save time and ensure a safer workspace.

Tip: Always wear a dust mask or respirator during sanding, regardless of the tool's dust collection capabilities, to protect yourself from inhaling fine particles.

Sandpaper Attachment

The way sandpaper is attached to a sander can affect how quickly you can swap sheets and how efficiently you work. Drywall sanders and orbital sanders use different methods of attachment and sandpaper designs, making it important to choose the right type for your project.

- Drywall Sanders:

Drywall sanders typically use large, circular sandpaper discs. These are attached using either a hook-and-loop (Velcro-style) system or clamps, allowing for quick and secure changes. Since drywall sanding involves large surfaces, these bigger discs cover more area and reduce the time needed for sanding. However, they tend to be more expensive than smaller orbital sandpaper pads. - Orbital Sanders:

Orbital sanders use smaller, rectangular sheets or circular pads, depending on the model. Most orbital sanders feature a hook-and-loop system for fast sandpaper changes, whilst others rely on adhesive backing. The smaller size of the sanding pads makes them ideal for precision work but less efficient for covering large areas. For detailed woodworking projects, the availability and affordability of orbital sandpaper make it a convenient choice.

Choosing the Right Grit: Selecting the right grit level is essential for achieving the desired finish (read our guide: The P Grades of Sandpaper Explained). For drywall sanders, coarser grits (e.g. 80–120) are suitable for removing joint compound, while finer grits (e.g, 150–220) help achieve a smooth surface ready for painting. Orbital sanders often use a wider grit range, from coarse grits for material removal to ultra-fine grits (e.g., 320–400) for polishing wood or finishing between coats of paint.

Tip: Keep extra sandpaper on hand to avoid interruptions during a project. For larger drywall jobs, consider buying sanding discs in bulk to save costs.

Cost

Drywall sanders with built-in dust collection and extendable handles typically cost more, while entry-level orbital sanders can be budget-friendly options, ideal for smaller projects.

Generally, drywall sanders are usually more expensive due to their specialised design and larger size. These tools are built to handle extensive surfaces and often include additional features like dust collection systems and extendable handles, which contribute to the higher price.

Orbital sanders, on the other hand, tend to be more affordable and versatile, making them a popular choice for both professionals and DIY enthusiasts.

They are available at a wide range of prices, from budget-friendly models to high-end options with advanced features.

When deciding between these sanders, consider not only the upfront cost but also how often you’ll use the tool and the need for features like dust collection and power.

Power Source

The power source of a sander plays a crucial role in its performance and ease of use. Both drywall sanders and orbital sanders are available in corded and cordless models, each with its own advantages and limitations.

- Drywall Sanders:

Most drywall sanders are corded, providing a steady and reliable power supply for extended use. This is particularly important when working on large surfaces like ceilings or entire walls, where consistent power is essential. Cordless drywall sanders are less common but can be useful for smaller jobs or when working in areas without easy access to power. However, cordless models often have shorter battery life and less power compared to their corded counterparts. - Orbital Sanders:

Orbital sanders are widely available in both corded and cordless versions. Corded models are ideal for longer tasks, as they provide continuous power without interruptions. Cordless orbital sanders, on the other hand, offer greater flexibility and mobility, making them suitable for smaller, quick jobs or when working in tight spaces. Modern cordless models with high-capacity batteries can deliver impressive performance, but they may still need recharging during extended projects.

What to Consider:

- Project Duration: If you’re working on a large area that requires continuous sanding, a corded sander is the better option.

- Mobility Needs: For smaller, detail-focused projects or when portability is key, a cordless orbital sander might be more convenient.

- Workspace: If your workspace has limited access to power outlets, cordless models offer more freedom but ensure you have a spare battery if the project is time-sensitive.

Tip: When choosing a power source, think about how often you’ll use the tool. For frequent, heavy-duty work, a corded drywall sander provides consistent performance. For occasional use or quick fixes, a cordless orbital sander adds convenience without compromising results.

Weight

The weight of a sander can significantly impact how comfortable it is to use, especially for extended periods or when working on ceilings and walls. Drywall sanders and orbital sanders differ greatly in their weight, which reflects their intended purpose and design.

- Drywall Sanders:

Drywall sanders are larger and heavier than orbital sanders, with most powered models weighing between 3.5kg and 6kg. Features like extendable handles and motorised heads contribute to the added weight, but these are necessary for covering large surfaces effectively. When sanding ceilings or high walls, the heavier design can lead to fatigue over time, especially for users who aren’t accustomed to the extra effort required to manoeuvre these tools. - Orbital Sanders:

Orbital sanders are much lighter, typically weighing around 1.5kg to 3kg. Their compact size and lightweight design make them easy to control and comfortable to use for precision work or extended sanding sessions. This makes them an ideal choice for projects like furniture refinishing, where detail and manoeuvrability are key.

What to Consider:

- Project Size: For large-scale projects like smoothing drywall or sanding ceilings, you’ll need to account for the weight of a drywall sander and the potential strain it might cause over time.

- Ergonomics: If you’re sanding intricate or small surfaces, the lighter weight and better control of an orbital sander will make your job easier and reduce fatigue.

Tip: If you need a drywall sander but are concerned about the weight, look for models with ergonomic handles or consider taking breaks during use to avoid strain. For orbital sanders, focus on grip comfort and balance for better control during precision work.

Choosing between a drywall sander and an orbital sander comes down to understanding your project’s needs. Drywall sanders are purpose-built for large, flat surfaces like walls and ceilings, offering speed and efficiency for tasks that require extensive sanding. In contrast, orbital sanders excel at detailed work, providing precision and control for smaller projects, such as furniture refinishing or cabinetry.

When making your decision, consider factors like dust collection, cost, power source, weight, and the scale of your project. If you’re tackling a large drywall job, investing in a powered drywall sander with features like extendable handles and dust extraction will save you time and effort. For smaller, detail-oriented tasks, a versatile orbital sander is likely the better choice.

If you’re still unsure which sanding tool is right for you, assess the most common projects you undertake. Do you spend more time sanding large surfaces, or is your focus on precision work? Alternatively, you can consult a professional at Heamar who will be able to advise on the most suitable sanding tool for your task at hand.