Torque wrenches are manufactured with a mechanism that limits the amount of torque a user is able to apply using the wrench. This type of torque-limiting mechanism is what differentiates types of torque wrenches and the technology that allows them to function.

This blog explains how susceptible the torque-limiting mechanism featured in click torque wrenches is to torque failures, and how the mechanism in cam-over torque wrenches safeguards against fastener failings and over-torquing.

Why is it Important to Choose the Right Torque Wrench?

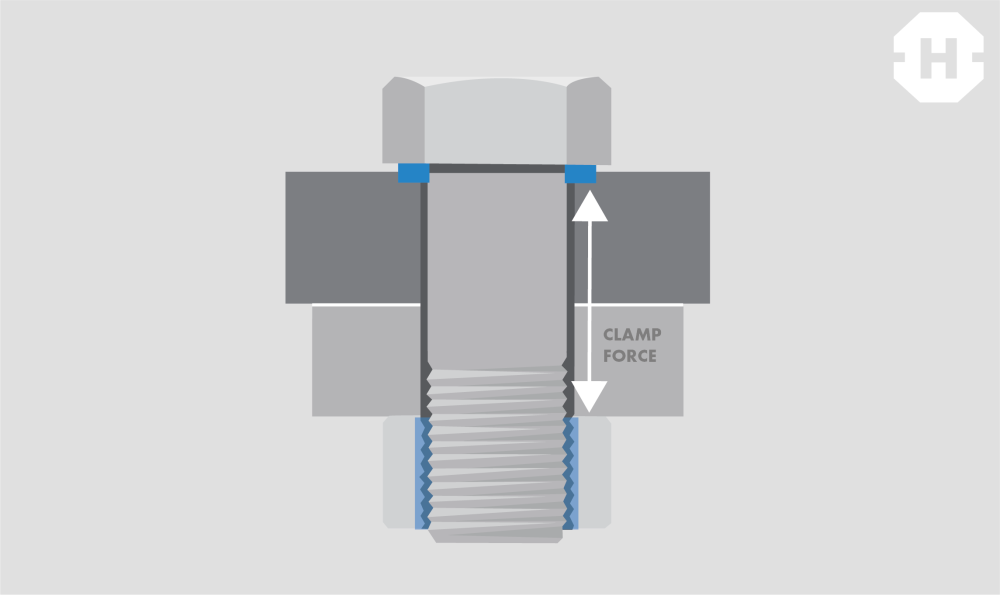

Torque wrenches are produced to provide the user with the best torque control possible. Good torque control allows for the correct clamp force. Fasteners stretch as they are tightened and so need the correct clamp force to ensure they won’t be damaged or under/over-torqued.

There are risks when not choosing the right torque wrench for you. If fasteners are under-torqued then there won't be enough clamp force. This can cause fasteners to vibrate and loosen. If fasteners are over-torqued, too much stress will be applied, and the fastener can over stretch and won’t be able to hold the amount of force being applied to it. Consequently, it will shear or break causing knock-on effects.

What is a Click Torque Wrench?

A click torque wrench is a very common variety of torque wrench. They are accurate and provide a good, audible signal when the correct torque has been achieved.

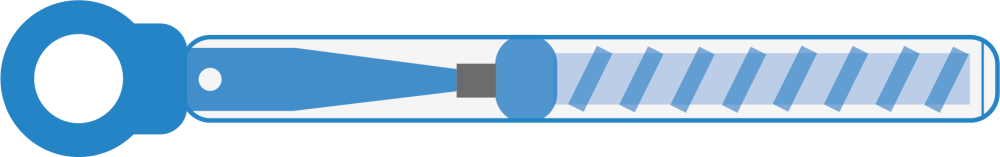

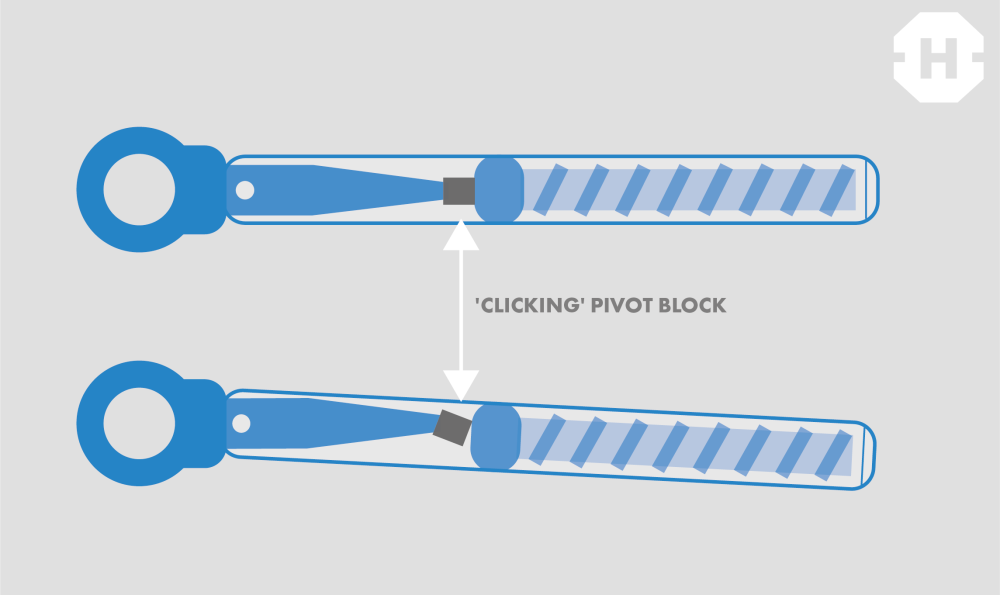

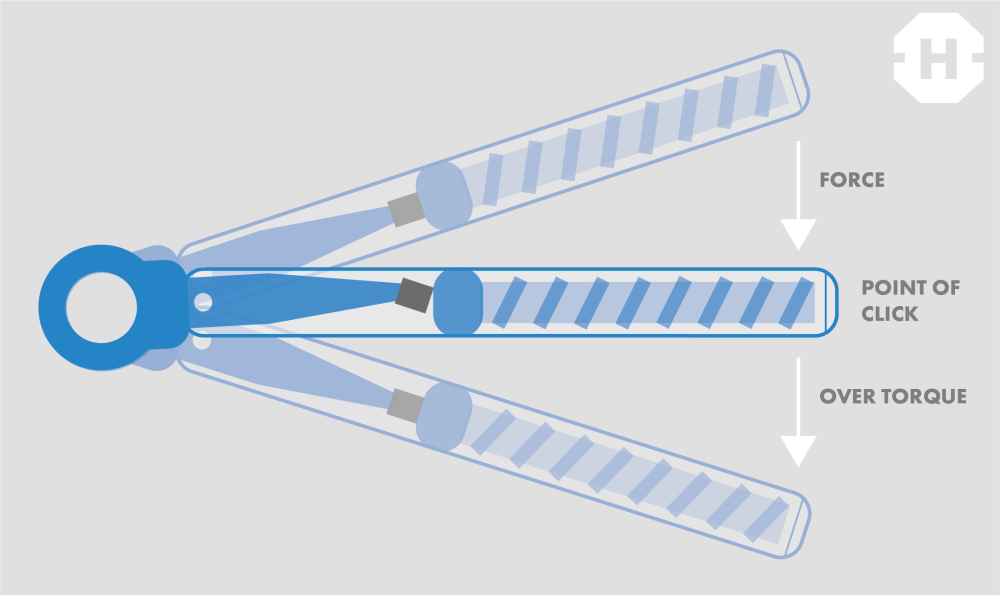

Click torque wrenches feature an internal spring mechanism that is compressed against a lever. As force is applied to the wrench the internal spring is compressed. When the predetermined torque amount is reached, the pivot block lifts and hits the inside wall of the torque wrench, which produces the signature ‘click’ sound.

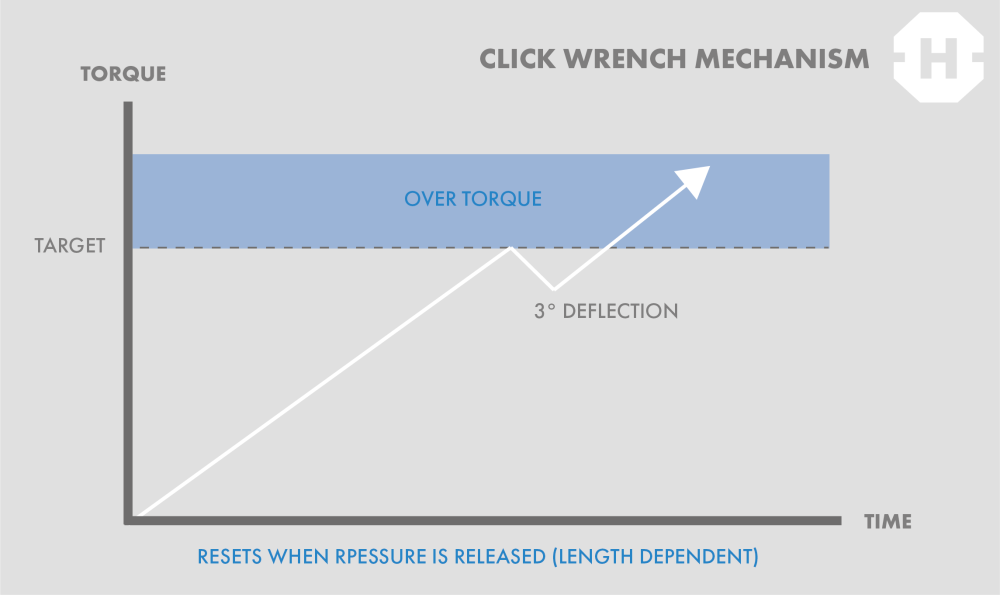

There is only a very small window of time for the user to stop applying force to the wrench once the click has been heard, to avoid adding additional torque to the assembly. A click wrench typically has around 3° of deflection once the ‘click’ has been heard.

This graph shows the time vs torque for the click wrench mechanism. The target torque is achieved at the point when the wrench clicks. The small dip reflects the 3° of reflection and the subsequent rise in the graph shows the application of additional torque to the process.

There is nothing physically preventing the operator from adding additional torque after the ‘click’ and it is common for the user to miss the ‘click’ sound or not feel the click movement in the wrench. Consequently, the click torque wrench mechanism is not 100% safe from over-torquing and is easily susceptible to torque failures and over-torque results.

On average, the user will over tighten the joint by 12%. This can be a lot higher the more unskilled the user is; however, there will still be over-torquing even with a skilled user. This can be shown on a torque analyser, as it will show the target torque as well as the actual torque achieved.

The diagram above shows what happens if the user does not stop applying force in time. The momentum of the wrench being used will carry its movement forward if force application is not stopped in time. As a result, there will be an over-torque issue.

What is a Cam-Over Torque Wrench?

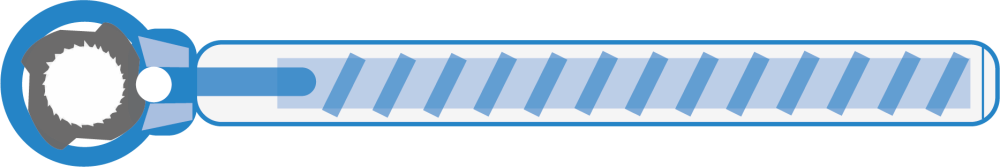

A cam-over torque wrench directly prevents over-torquing. This type of torque wrench features an internal cam-over mechanism, which physically prevents the operator from over-torquing fasteners by slipping or disengaging once the required torque has been reached.

If a user tries to use the tool on the same fastener once it has already slipped, the torque wrench will simply slip again and refuse to deliver more torque than the value the wrench has been locked to. There is no adjustable scale on this tool, which allows the user to hit the torque value required without having to worry about what torque the tool has been previously adjusted to.

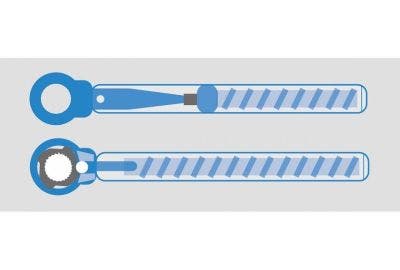

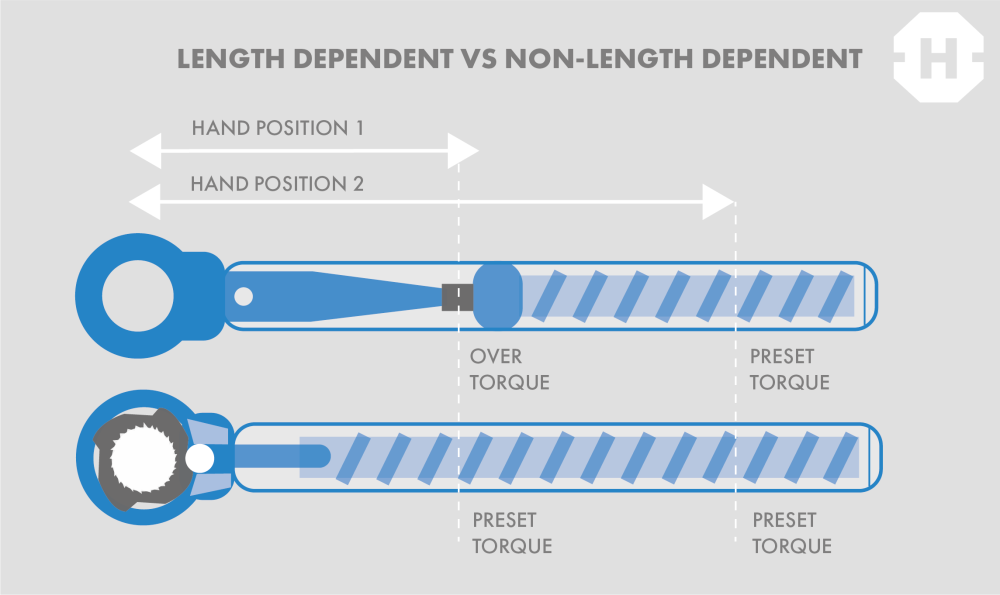

Cam-over wrenches are also non-length dependent, unlike click wrenches. The pivot point inside the tube of a click wrench is on a fulcrum point. This means that if a user holds the wrench with their hand anywhere other than where it has been specifically designed to be held, then the user will be changing the formula of force x distance. Consequently, yet another error will be introduced to the torquing process. The pivot point in a cam-over wrench is on the end of the tool which allows the user to hold the wrench anywhere up and down the handle and still produce the same amount of torque.

The type of mechanism used inside cam-over wrenches safeguards against fastening failures and removes any user error from the equation. It delivers an accurate and repeatable fastening result every time, especially when compared to a standard click wrench.

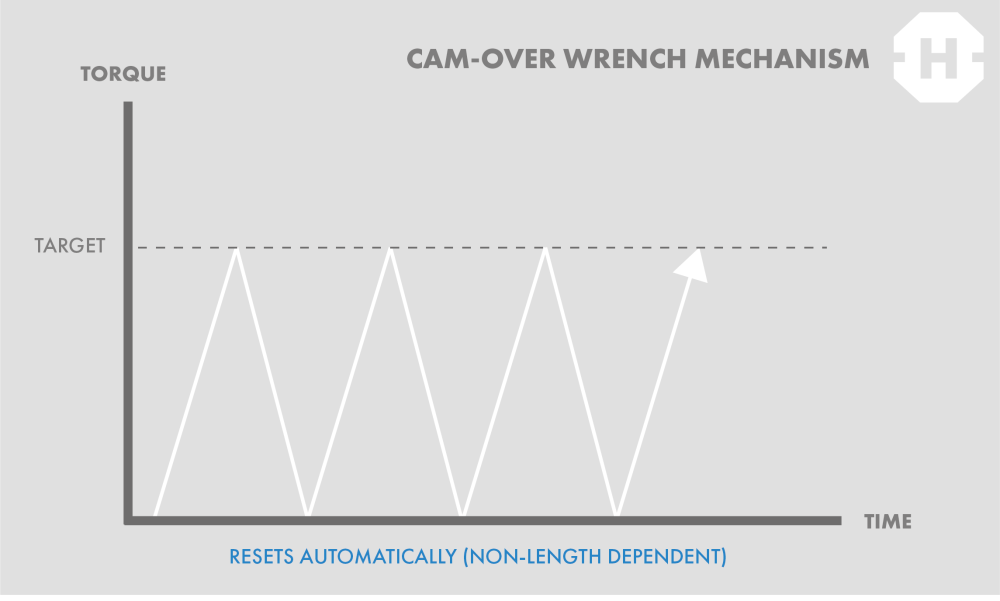

The graph above shows exactly how cam-over wrenches achieve the same, accurate torque target time and time again. This total control of the torque delivery from cam-over wrenches means they are perfect for critical torque applications where mistakes cannot be tolerated.

Should I Choose a Click Wrench or a Cam-Over Wrench?

Click torque wrenches are incredibly popular due to their price point in comparison to other types of torque wrenches. However, as explained above, a click wrench does not stop the user from over-torquing. It will only indicate with a sound when the user has reached the required torque. A cam-over torque wrench is an upgrade from a click wrench, as it physically prevents the user from applying too much torque.

When under or over-torquing puts your products at risk, cam-over wrenches deliver the accuracy you need and eradicate user error. By investing in a cam-over wrench you will be error-proofing the tightening process and consequently improving the quality control method. This is due to the reduction in numbers of defective products that will be pulled from the assembly line thanks to the cam-over wrench's inability to over-torque.

Preset cam-over torque wrenches are the best tools for high-level processes and quality control. Their repeatability and precision guarantees quality assurance in the tightening process.

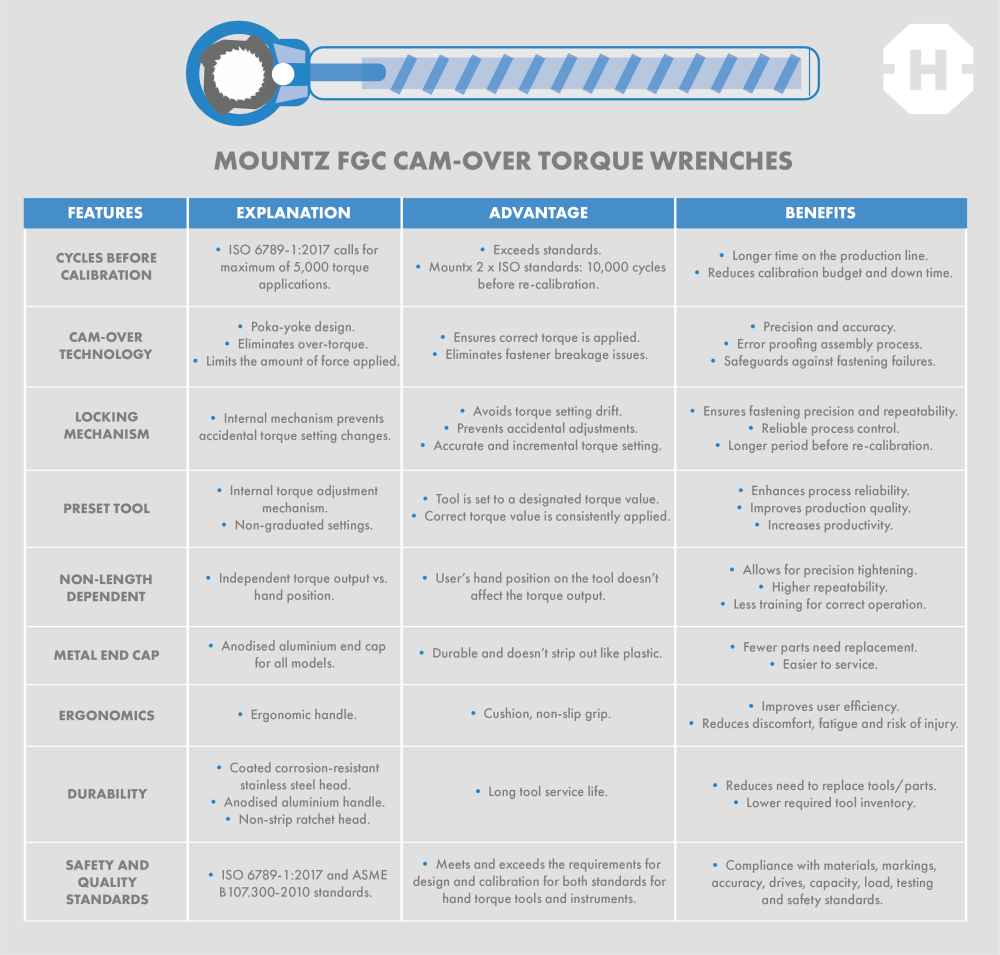

Mountz FGC Cam-Over Torque Wrenches

The Mountz FGC range of precision preset cam-over wrenches are the most advanced torque wrenches for high-level processes and quality control. These tools are set to a designated torque value and as such the correct value is consistently applied. They are ideal for fastening applications where operators repeatedly assemble parts at the same torque setting.

Heamar sell a variety of torque wrenches, as well as a wider range of torque tools.