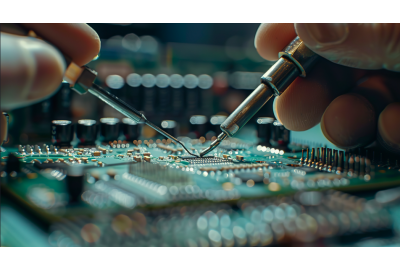

Selecting the right soldering iron tip is just as important as choosing the soldering iron itself. The tip directly affects precision, efficiency, and the overall quality of solder joints. Whether you are working on intricate electronics, general PCB soldering, or large industrial components, using the correct tip ensures strong and reliable connections.

Many people rely on a single tip for all tasks, but this can result in poor solder joints, overheating or inefficient heat transfer. Each tip shape is designed for specific applications and provides different levels of control, heat distribution and ease of use.

This guide explains the most commonly used soldering iron tip types—chisel, conical, hoof, knife, and cartridge-format tips—along with their advantages, best uses, and maintenance recommendations. By the end, you will have a clear understanding of which tip is best suited to your needs and how to care for it to ensure long-term performance.

Understanding Cartridge vs. Standard Soldering Tips

Before looking at different tip shapes, it is important to distinguish between cartridge-format tips and standard soldering iron tips.

Cartridge tips integrate the heating element and temperature sensor inside the tip itself. This design ensures fast heat transfer, stable temperature control and consistent performance. Cartridge tips come in various shapes, such as chisel, conical, and hoof, and require a compatible soldering station.

Standard tips attach to the heating element of a traditional soldering iron and do not contain a built-in heater. Heat transfer depends on the thermal efficiency of the iron, and tip changes typically take longer compared to cartridge systems.

While cartridge tips are a format rather than a shape, they are widely used for high-precision work and industrial soldering.

Chisel Tips (Wedge or Screwdriver Tips)

Best Uses

Chisel tips are one of the most commonly used soldering tips due to their ability to distribute heat evenly. They are well-suited for general-purpose soldering, through-hole components, PCB pads and wire connections. Their wide surface area allows for efficient heat transfer, making them effective for larger solder joints.

Advantages

Chisel tips provide excellent heat distribution because of their flat, wide edge, ensuring even solder melting. They are versatile and can be used for both small and large components, depending on the tip size. Their broad contact area also makes them effective for desoldering, as they can quickly remove excess solder.

How to Use a Chisel Tip Effectively

For optimal results, a chisel tip should be approximately 60 percent of the pad width. The flat surface of the tip should be placed directly against the joint to ensure even heating. Cleaning the tip regularly with a brass pad or damp sponge will maintain efficiency and extend its lifespan.

Conical Tips (Precision Tips or B Series Tips)

Best Uses

Conical tips are ideal for fine electronic work, circuit board repairs and soldering small, delicate connections. Their sharp point allows for high-precision soldering, making them particularly useful for working on surface-mount components.

Advantages

The pointed tip enables precise solder application, making conical tips well-suited for intricate soldering tasks. The small contact area helps prevent excess solder from spreading, which is particularly useful for avoiding solder bridges. Conical tips are also commonly used by beginners due to the ease of controlling solder placement.

Limitations

Conical tips are less effective for large solder joints because their narrow tip does not transfer heat as efficiently as broader tips. The small surface area in contact with solder can cause them to wear out more quickly than chisel tips. Careful cleaning is required, as oxidation can accumulate on the fine point, affecting performance.

How to Use a Conical Tip Effectively

For better heat transfer, the side of the tip should be used rather than relying only on the extreme point. Excessive pressure should be avoided to prevent tip damage. Keeping the tip well-tinned helps to prevent oxidation and ensures optimal performance.

Hoof Tips (Concave Bevel Tips or CM Series Tips)

Best Uses

Hoof tips are well-suited for drag soldering, reflowing solder, and high-efficiency solder application. Their curved surface allows them to hold a small reservoir of solder, which makes them particularly effective for soldering multiple pins in a single pass.

Advantages

The concave shape of a hoof tip allows for smooth and controlled solder application, reducing the risk of solder bridges. This tip type is ideal for surface-mount soldering, particularly when working with integrated circuits and components that require consistent solder flow.

Related Tip: Bevel Tip

Bevel tips are similar to hoof tips but lack the concave surface. A standard bevel tip offers similar heat distribution but does not hold solder in the same way, making it more suitable for general soldering applications rather than drag soldering.

How to Use a Hoof Tip Effectively

A gentle dragging motion should be used when soldering multiple pins to ensure even solder distribution. Keeping the concave surface tinned improves heat transfer and prevents oxidation. Temperature adjustments should be made carefully to avoid overheating delicate components.

Knife Tips (Blade Tips or Type K Tips)

Best Uses

Knife tips are primarily used for soldering rework, removing solder bridges and accessing tight spaces where standard tips may not fit. They are effective for cutting through excess solder and modifying solder joints in small, confined areas.

Advantages

The flat, sharp edge of a knife tip makes it highly versatile for both precision soldering and solder removal. It is particularly useful for reworking circuit boards, lifting excess solder, and soldering in confined spaces.

How to Use a Knife Tip Effectively

The edge of the tip can be used for controlled solder application, while the flat surface is effective for removing solder bridges. Excessive force should be avoided, as the thin edge can wear down more quickly than other tip shapes.

Cartridge Tips (Integrated Heater Tips)

Best Uses

Cartridge tips are commonly used in industrial and high-precision soldering applications where stable temperature control is essential. They are ideal for surface-mount work, fine electronics assembly, and tasks that require consistent heat delivery.

Advantages

Cartridge tips heat up quickly and provide stable temperature control, minimising the risk of overheating components. They are easy to replace, allowing users to swap tips efficiently for different tasks.

Soldering Tip Maintenance: Best Practices

- Keep the tip well-tinned at all times to prevent oxidation.

- Use tip tinner paste to restore performance if oxidation builds up.

- Clean the tip with brass wool or a damp sponge to remove flux residues.

- Avoid using excessive heat, as this accelerates oxidation and shortens tip lifespan.

- Do not file or sand tips, as this removes the protective iron plating.

| Tip Types | Best For | Key Advantage |

| Chisel | General soldering, large components | Even heat distribution |

| Conical | Fine electonics, precision work | Small, controlled solder joints |

| Hoof | Drag soldering, SMT applications | Holds solder for smooth application |

| Knife | Rework, solder removal | Fits into tight spaces, removes excess solder |

Find the Right Soldering Tip for Your Needs

Choosing the correct soldering iron tip can transform the quality, efficiency, and precision of your work. Whether you're assembling delicate electronics, tackling industrial projects, or performing intricate rework, the right tip makes all the difference.

Explore Heamar’s extensive range of soldering tips and tools to find the perfect fit for your application. With high-quality options from trusted brands, you’ll have the right equipment to achieve professional-grade results.