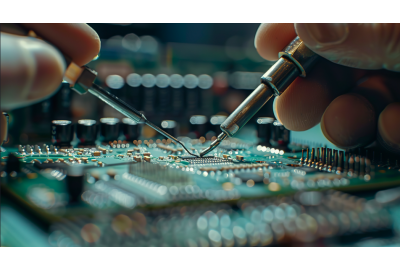

Well-maintained soldering tips are essential for achieving clean, precise connections, whether you’re working on detailed electronics projects or quick repairs. Over time, wear and tear on the tip can impact both the quality of your work and the ability to achieve consistent results. Recognising when a tip has worn out can save time and make soldering more efficient.

In this article, we’ll outline key signs that indicate when to replace a soldering tip. With these insights, you can keep your soldering equipment performing at its best, improving results and extending the life of your tools.

Signs of Wear on a Soldering Iron Tip

Discolouration or Oxidation

With regular use, a soldering iron tip naturally oxidises due to air exposure, causing it to change colour. While light discolouration is normal, severe oxidation often results in a darkened or blackened tip, which indicates extensive wear. This can reduce heat transfer efficiency and prevent the solder from adhering smoothly to the surface, affecting the quality of your soldering work.

Routine cleaning can minimise oxidation, but if the tip remains darkened or is unable to hold solder well despite cleaning, it may be time to consider a replacement.

Irregular or Deformed Tip Shape

Frequent use can cause the soldering iron tip to lose its original shape, becoming rounded, uneven or slightly deformed. A worn tip affects precision, making it harder to control solder flow and achieve neat connections. In some cases, light filing can help restore the shape, but excessive deformation is often beyond repair and warrants a new tip.

To maintain precision, regularly inspect the tip for noticeable changes in its shape or alignment. Consistent irregularities, even after attempts to reshape, indicate the need for a replacement to provide optimal soldering quality.

Impact of a Worn Tip on Soldering Performance

Poor Heat Transfer

A damaged or worn soldering iron tip often struggles to transfer heat effectively, leading to uneven soldering results. Signs of poor heat transfer include longer soldering times or difficulty melting solder, both of which impact the speed and quality of your work. Inconsistent heat not only affects the durability of solder joints but can also lead to frustration as the solder doesn’t flow smoothly.

Additionally, a tip that fails to conduct heat well places added stress on the soldering iron, potentially reducing the lifespan of the tool itself. If you notice these signs despite cleaning the tip, it’s likely time for a replacement.

Inconsistent Solder Flow

A worn tip can prevent solder from flowing smoothly across connections, creating issues like cold joints or weak solder connections. Cold joints occur when the solder doesn’t melt and adhere properly, leaving connections that may fail under strain. A well-maintained tip provides consistent solder flow, essential for accurate and reliable soldering.

If the inconsistent flow continues even after thoroughly cleaning the tip, replacement is often the best solution to achieve smooth and secure joints in your projects.

How to Inspect and Test Your Soldering Iron Tip

Visual Inspection

A regular visual check of the soldering iron tip helps to spot early signs of wear. Inspect the tip’s colour, shape and surface condition after cleaning it, as residue can sometimes mask underlying damage. Look for uneven surfaces, discolouration, cracks, or other visible signs of wear that could impact performance. With frequent visual checks, you can catch issues early and maintain consistent soldering quality.

Simple Performance Test

Performing a quick heat transfer check is an easy way to test the tip’s effectiveness.

Apply solder to the tip and observe how quickly it melts and flows. If the solder doesn’t melt smoothly or evenly, it may indicate reduced performance due to wear. When this happens consistently, even after cleaning, it’s often a sign that the tip has reached the end of its usable life and should be replaced.

Proper Tip Maintenance to Extend Lifespan

Cleaning the Tip Regularly

Regular cleaning is essential to keep your soldering iron tip in good working condition. After each use, clean the tip with a damp sponge or brass wool to remove any oxidation or residue. This helps to prevent buildup, which can reduce heat transfer efficiency and make soldering more challenging. You should avoid using abrasive cleaners, as they can damage the tip’s surface, leading to quicker wear. By maintaining a regular cleaning routine, you can significantly extend the lifespan of the tip.

Using the Right Tip Temperature

Excessive heat can cause rapid oxidation and structural weakening of a soldering iron tip, so it’s best to set the temperature appropriately for the material you’re working with. High temperatures may speed up tip degradation, resulting in frequent replacements. Adjust the temperature based on the type of solder and material to prevent overheating and minimise wear. Effective temperature control not only improves soldering precision but also protects the tip, helping it to last longer.

When Replacement Is Necessary: Key Considerations

Frequency of Use

The lifespan of a soldering iron tip largely depends on how often it’s used. For those who solder frequently, the tip will naturally wear out faster and require closer monitoring for signs of degradation. Frequent users should check their tip more regularly to determine if a soldering iron tip replacement is needed, while occasional users may find that their tip lasts much longer between replacements. Consistently evaluating the tip’s condition based on usage helps maintain optimal performance.

Cost vs. Performance

There’s often a balance between the cost of replacing a soldering tip and the performance it delivers. Investing in a high-quality tip can lead to better heat consistency and precision, potentially lasting longer than budget options.

If soldering performance issues such as poor heat transfer or irregular solder flow persist despite maintenance, it’s likely time for a replacement, even if the tip appears usable. Prioritising consistent, reliable results over cost alone can lead to better outcomes in your projects.

Regular monitoring of your soldering iron tip and maintenance can make a noticeable difference in the quality and efficiency of your work. By keeping an eye out for soldering tip wear signs—like discolouration, deformed shape, or poor heat transfer—you can address issues before they impact your projects. A worn tip can compromise soldering quality and precision, so it’s essential to perform regular checks and soldering iron tip maintenance.

When cleaning and inspection no longer restore the tip’s performance, replacement is the best step to provide reliable results. For further advice or to purchase replacement tips, feel free to contact us at Heamar.