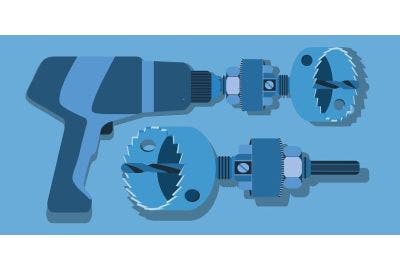

A hole saw is a versatile tool every DIY enthusiast and professional tradesperson should consider for their toolkit. Known for its ability to drill clean, round holes in various materials, a hole saw is essential for tasks requiring precision and efficiency. Its applications range from home improvement projects to professional installations, proving its adaptability and usefulness.

In this article, we explore the top five hole saw applications, showcasing their value across different tasks. Whether you're installing door knobs, cutting holes in pipes, or setting up HVAC ducts, understanding how to use a hole saw effectively can save you time and effort.

Installing Door knobs and Deadbolts

Installing door knobs and deadbolts demands precision to ensure the lock functions smoothly and securely. A poorly drilled hole can lead to misalignment, making the lock ineffective and compromising the door’s security. Here, a hole saw proves invaluable by creating perfectly round, smooth holes tailored for doorknobs and deadbolts.

Key Considerations:

- Size Matters: Most standard door knobs and deadbolts require a hole diameter of 2 1/8 inches, but always verify the manufacturer’s specifications before beginning.

- Safety First: Secure the door using clamps to prevent movement during drilling. Always wear protective eyewear and gloves to guard against debris.

- Technique Tips: Set your drill to the appropriate speed to avoid splintering the door material. Mark the exact spot for the hole with a pencil or template to ensure alignment.

By using a hole saw, you not only streamline the installation process but also achieve professional results with minimal effort. A properly installed lock not only enhances security but also improves the overall appearance of the door.

Cutting Holes in Pipes

Precision is key when cutting holes in pipes, whether for plumbing installations or fitting components like valves or spigots. A hole saw ensures clean, accurate holes that minimise the risk of damaging the pipe, making it an indispensable tool for this task.

Best Practices:

- Match the Material: Use a bi-metal hole saw for metal pipes and a carbide-tipped hole saw for tougher materials like cast iron. For PVC pipes, a standard hole saw is sufficient.

- Preparation is Crucial: Secure the pipe firmly to prevent movement during drilling. Mark the exact location for the hole using a pencil or marker.

- Drilling Tips: Apply steady, even pressure to avoid cracking or deforming the pipe. Keep the drill at a consistent speed to achieve a smooth cut.

Common Mistakes to Avoid:

- Using an incorrect hole saw type for the material, which can result in rough edges or even pipe damage.

- Applying excessive pressure, which can lead to fractures in the pipe material.

By following these guidelines, you can ensure clean, precise holes that allow for easy installation of fittings and other components, making your plumbing projects smoother and more efficient.

Implementing HVAC Ducts

Installing HVAC systems requires precise openings for ductwork to ensure optimal airflow and system efficiency. A hole saw simplifies this process, enabling clean, accurately sized cuts through materials like drywall, wood and even metal.

Tips for Success:

- Plan the Placement: Measure the duct size carefully and mark the exact location for the hole. Proper placement prevents misalignment and ensures effective airflow.

- Choose the Right Hole Saw: Use a bi-metal hole saw for cutting through metal ducts and a standard hole saw for materials like drywall or wood.

- Maintain Precision: Secure the material firmly to avoid vibrations that could lead to uneven cuts. A steady hand and consistent drill speed are key to achieving smooth results.

Prevent Air Leaks:

- To ensure a proper seal around the duct, cut the hole slightly smaller than the outer flange of the ductwork. This allows for a snug fit and easier sealing.

- Inspect the edges of the cut for any roughness and sand them smooth if necessary to prevent gaps.

- By using a hole saw, you can create duct openings that contribute to the overall efficiency of the HVAC system. Accurate cuts minimise air leaks, helping maintain consistent temperatures and reducing energy costs.

Making Openings for Speakers

Installing speakers in walls or ceilings requires precise cuts to ensure both a professional finish and optimal sound quality. A hole saw is an excellent choice for creating the perfect openings for in-wall and in-ceiling speakers, blending functionality with a polished appearance.

Steps to Achieve a Perfect Speaker Installation:

- Measure and Mark: Begin by measuring the speaker diameter and marking the location of the hole. Most speaker kits include a paper template—use this to ensure accuracy.

- Select the Correct Hole Saw: Match the hole saw size to the speaker dimensions for a snug, secure fit. Double-check the manufacturer’s recommendations for best results.

- Prepare the Surface: Secure the wall or ceiling material to minimise vibrations during drilling. This is especially important when working with drywall.

- Drill with Care: Align the hole saw correctly and drill at a steady speed to prevent jagged edges. Avoid rushing, as this can damage the surrounding material.

Key Considerations:

- Before drilling, check for hidden electrical wiring or plumbing behind the wall or ceiling using a stud finder or similar tool.

- To protect the surrounding surface, use painter’s tape around the marked area to minimise chipping or scuffing during the drilling process.

- Do not be fooled by the size given on a speaker’s product listing. Normally there are two sizes provided; the size of the speaker’s woofer, and the size of the full width of the speaker with its grill attached. Trust in the template provided to you!

By using a hole saw and following these steps, you can achieve a clean, professional-grade speaker installation that enhances your home audio system while maintaining a sleek aesthetic.

Drilling Holes for Cable Pass-Throughs

Efficient cable management is essential for maintaining both functionality and aesthetics in modern homes and offices. A hole saw allows you to create clean, precisely sized holes for cable pass-throughs in desks, walls, or entertainment units, simplifying the organisation of wires and preventing tangling or damage.

Step-by-Step Guide:

- Identify the Location: Choose a discreet yet functional spot for the pass-through, ensuring it won’t obstruct daily activities or device connections.

- Measure the Cable Bundle: Group the cables and measure their combined thickness to determine the appropriate hole saw size. This prevents a hole that’s either too tight or excessively large.

- Prepare the Material: Secure the surface you’re drilling into to prevent movement. For example, clamp a desk or stabilise a wall panel before starting.

- Drill the Hole: Mark the spot and drill steadily, ensuring the material doesn’t splinter or fray.

Additional Tips:

- For a polished look, use a grommet or cable cover to protect the edges of the hole and enhance its appearance. Grommets are available in various sizes and materials to suit different styles and needs.

- When working with metal or hardwood, use a bi-metal hole saw to achieve a smooth cut without damaging the tool or the material.

By following these steps, you can create neat, professional cable pass-throughs that improve the organisation and longevity of your cables, ensuring a tidy and efficient setup.

A hole saw is a versatile and indispensable tool for anyone tackling home improvement or professional tasks. Its ability to create precise, clean holes across various materials makes it an essential addition to any toolkit. From installing door knobs and cutting pipes to setting up HVAC ducts, creating speaker openings, and managing cables, the applications of a hole saw are both varied and practical.

When choosing a hole saw, consider the material you’ll be working with and the size of the hole required to achieve the best results. Investing in a high-quality hole saw not only saves time but also prevents costly mistakes, ensuring professional-grade outcomes for every project.

If you’re looking to expand your tool collection or need expert advice, Heamar offers a wide range of high-quality hole saws and accessories to suit all your needs.